Middle East service provider

Engineers based in Dubai (U.A.E.), Saudi Arabia, Pakistan, Oman and many other Gulf countries. Central parts store in Dubai with satellite stores around the Middle East.

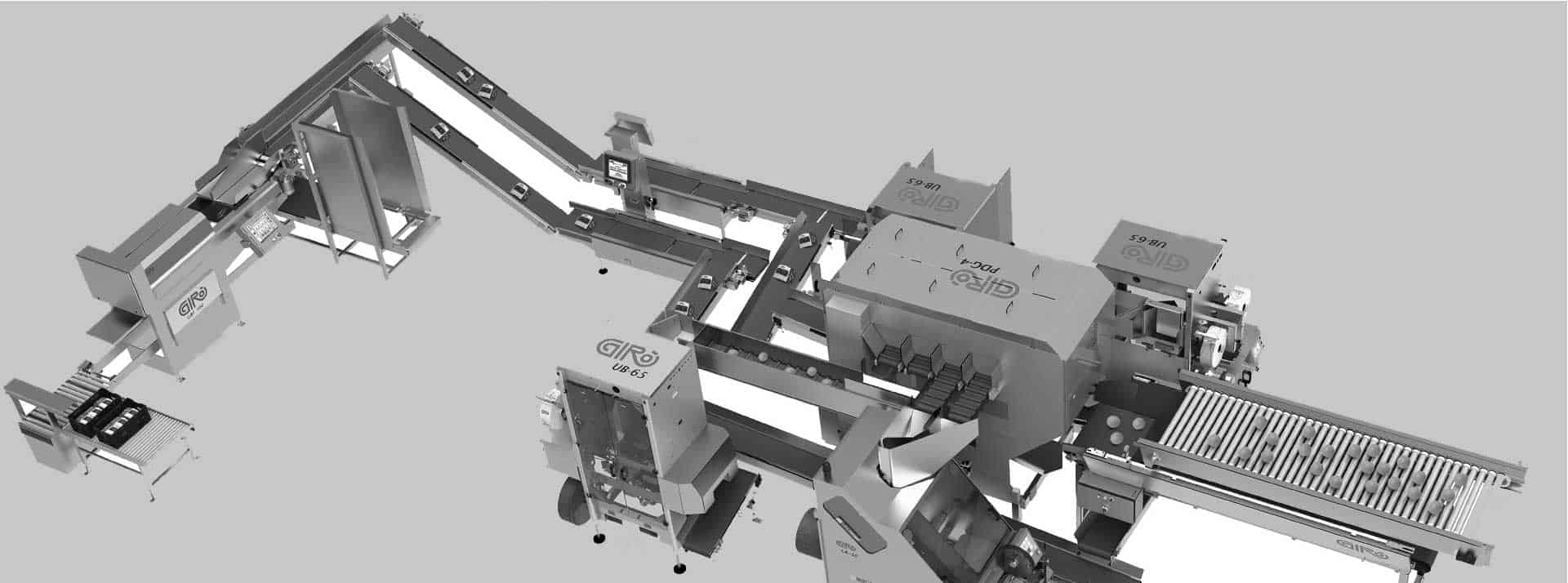

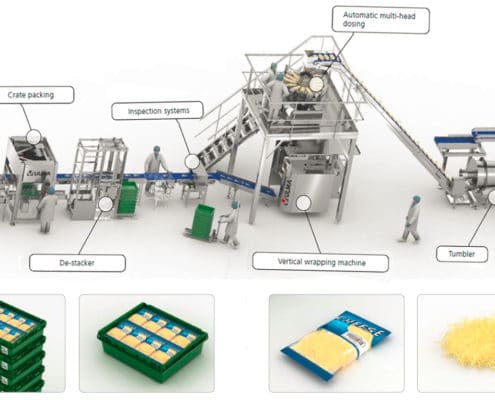

Integrated Packaging Lines

Project Management to provide our customers with a total end to end packaging solutions.

Brand protection

Al Thika provides our customers with up to date advice and inspection solutions to protect their brand.

Al Thika Packaging is fully aware of the rise in plastic consumption over the past years as well as the environmental effects of abandoned plastic waste.

Al Thika Packaging supports this shift in focus and, understanding of its position of responsibility within the industry, is working to make sure that its social contributions go beyond simply meeting regulatory requirements and serve as an example for our clients. For this reason, we are offering a wide range of sustainable packing machines.

MACHINERY SOLUTIONS BY AL THIKA PACKAGING

Coding printer

Markem Imaje is a leading manufacturer of coding and marking systems, offering a comprehensive range of products and technologies to meet every application.

Primary packaging machine

ULMA, specialised in the design and production of packing machine. With more than 50 years of experience and a team of highly qualified professionals, ULMA offers extensive and innovative packing solutions.

Product inspection system

Mettler Toledo offers a range of the industrial metal detector, X-Ray inspection, checkweigher and CI-vision systems which can help to detect contamination and other faults in most food and pharmaceutical applications.

Optical sorting machine

Al Thika Packaging is world renowned sorting machine supplier in the Middle East. we are providing sorter for dates, nuts, grains, potatoes, chips, fruit and vegetable and other food products. Ongoing innovations provide increased control, continuous processing and longer machine life–in processed fruits and vegetables, nuts, dried fruit, dates, fresh-cut produce and more.

SOLUTIONS FOR THE LOGISTICS & E-COMMERCE INDUSTRY

Al Thika offers a wide range of protective packaging (bubble wrap, void & cushion film), shrink wrap, stretch wrapping, pallet inverter, material handling, water-activated tape dispenser and data logger solutions tailored towards the logistics & e-commerce industry from leading manufacturers around the world. Meijer Handling Solutions the world’s market leader in hydraulic lift truck forks, known as KOOI-REACHFORKS®.

Application consumables & spare parts

An integral part of our business is the supply of genuine consumables, spare parts for use in our customers’ coding and marking equipment, banding, palnet and net bagging solutions, shrink and stretch wrapping machines.

Our world class partners

Industrial solutions

Providing complete packaging, wrapping, coding, inspection, sorting & protective packaging machine solutions to our customers for more than 20 years means that we have developed an intimate knowledge of a wide range of industries. Please follow one of the following links if you would like to know more about your specific application;