Mettler Toledo CM35 AdvancedLine Combi

Checkweighing and Metal Detection Combination

A throughput of up to 600 packs per minute, a weighing range from 3 g to 10 kg and extremely high weighing accuracy positions the C35 AdvancedLine at the vanguard of checkweighing and metal detector technology.

Customised Product Handling

Fully customisable with 250 performances and productivity enhancing options. Product handling variants include sidegrip conveyors, top and bottom conveyors, infeed timing screws and starwheels to ensure flawless product flow

Unparalleled in Challenging Environments

Designed for endurance and maximum reliability to perform in wet, dry and harsh working environments. Specialised conveyors are designed to match applications and production conditions

Advanced Metal Detector Integration

Available as a combination system with a large range of advanced Safeline Profile metal detectors to ensure that smaller footprints are achieved. Due diligence solutions make it ideal as a Critical Control Point for best possible quality.

| Throughput | 500 ppm |

| HMI | 15″ |

| Weighing Range | 5 g – 10 000 g |

| Preferences | Multi-lane Tare Gross Weighing |

| Product Width | 400 mm |

| Hygienic Requirement | Wipe Down ( |

| Maximum Product Weight | 10 kg |

| Combination Options | Vision Metal Detection |

| Transport Height | 550 mm – 1,100 mm (± 50 mm) |

| Industry | Food |

| IP Rating | IP54 (optional IP65) IP 65 |

| Accuracy | from ±0.01 g |

| Production Environment | Wet Dry |

| Weighing Technology (Load Cell) | EMFR |

| Customization Options | Bespoke handling OEM Multilane |

| Approval | Weights & measures design approval for official verification (MID certifiable) |

| Weighing Combinations | Contamination Detection |

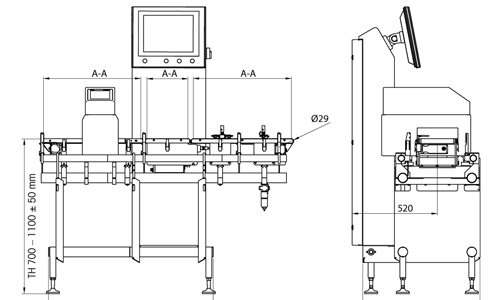

Click the image below to view the diagram.

CM35 AdvancedLine Features and benefits

| Simple integration and smooth operation In your production processes – with a maximum uptime and trouble-free refitting further down the line – from the start the system architecture is designed with practical scenarios in mind. |

|

| Up to 33% Higher Performance Implies high throughput with accuracy to promote tighter manufacturing tolerances in production. Improved processes mean an increase in overall equipment effectiveness to maximise your profits. |

|

| Protects Consumers and Brand Reputation From product transport to sorting equipment – every last component has been put to the test, as well as every hazardous area. As a result, the risk for material damage and injury is reduced. |

|

| “Built-in” Safety Plus An extensive service network guarantees timely support plus availability and quick delivery of spare parts. This reduces downtime and keeps processes running smoothly. |

|

| Extensive Service Support An extensive service network guarantees timely support plus availability and quick delivery of spare parts. This reduces downtime and keeps processes running smoothly. |

|

CM35 AdvancedLineA throughput of up to 600 packs per minute, a weighing range from 3 g to 10 kg and extremely high weighing accuracy positions the C35 AdvancedLine at the vanguard of checkweighing and metal detection technology. Its outstanding precision and versatility allow its use in all industrial production situations requiring 100 percent weight control, especially those where demanding and complex application requirements need to be achieved. The CM35 AdvancedLine can be equipted with specialised conveyors and handling options allow for the optimal transport of unstable or open products such as jars, trays and cans. The CM35 AdvancedLine has been designed to enhance production line performance, up-time availability and quality. In addition, it supports all current global food safety standards, legislation and regulations. |

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the main distributor of Mettler Toledo in Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision inspection systems in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.