SMIPACK FP560 – Manual L-sealers machine – shrink wrap

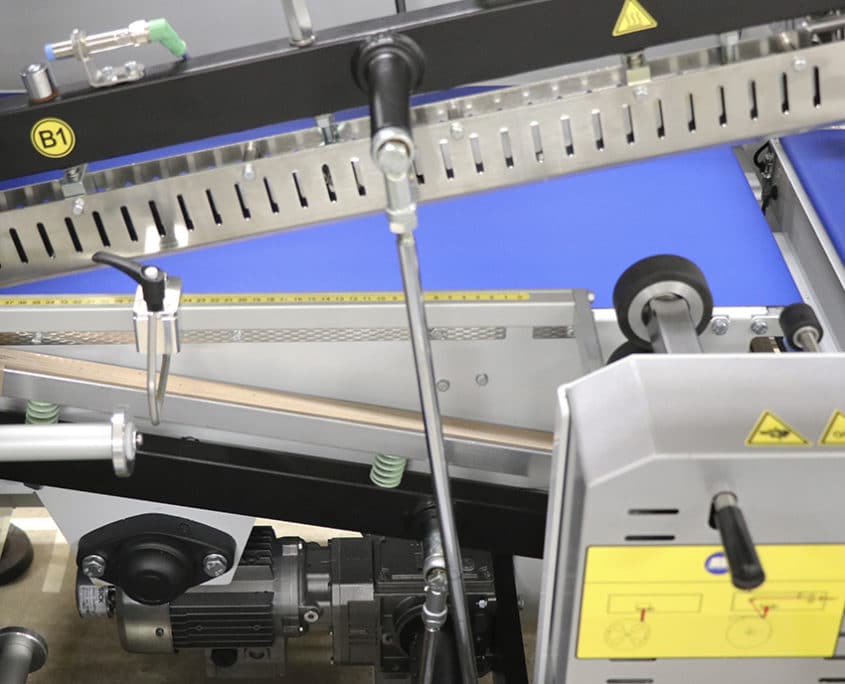

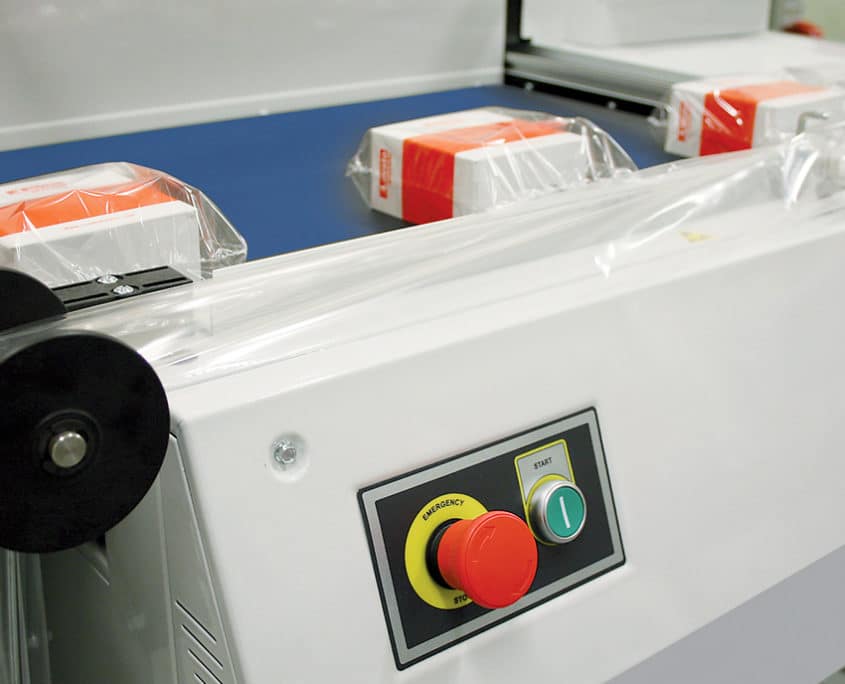

Modularity and excellent price/quality ratios are the main features characterising the manual, semiautomatic and fully automatic sealers of the Smipack FP series. All the models of this range can indeed be supplied with or without shrink tunnel.

The INOX version machines are ideal to satisfy the exigencies of the food industry (meat, frozen food, fish, dairy, bakery, cheese, chocolate, etc.), and are characterised by a stainless steel frame (AISI 304) and the conveyor complying with the FDA, UE and USDA standards, concerning products in direct contact with food.

Compared to the traditional L-sealers, the FP series provides higher outputs as well as the possibility of using Polyethylene film, besides the traditional shrink films, and includes different models for outputs ranging up to 3600 packs/hour.

Characteristics

| Power supply | 220 – 240 V |

| 1PH + N + PE | |

| 50/60 Hz | |

| Installed power | 2450 W |

| Sealing bar | 560 x 430 mm |

| Maximum pack height | 230 mm |

| Speed of conveyors | 19 m/min |

| Output up to | 800 pph ** |

| Maximum size of film reel | 600 – ø 300 mm |

| Machine size | 2010 x 790 mm |

| h 1050 mm | |

| Machine net weight | 129 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 50 µ |

(**) Packs per hour. The stated speed can change according to the product size, the pack collation and the type of film used.

Smipack – Al Thika Packaging LLC

Al Thika Packaging is the exclusive distributor of Smipack in the Middle East. Since 1994 Al Thika has been supplying best packaging machine including shrink wrappers, sealers & hood packers for food & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Kuwait, Oman and the many other Gulf countries.