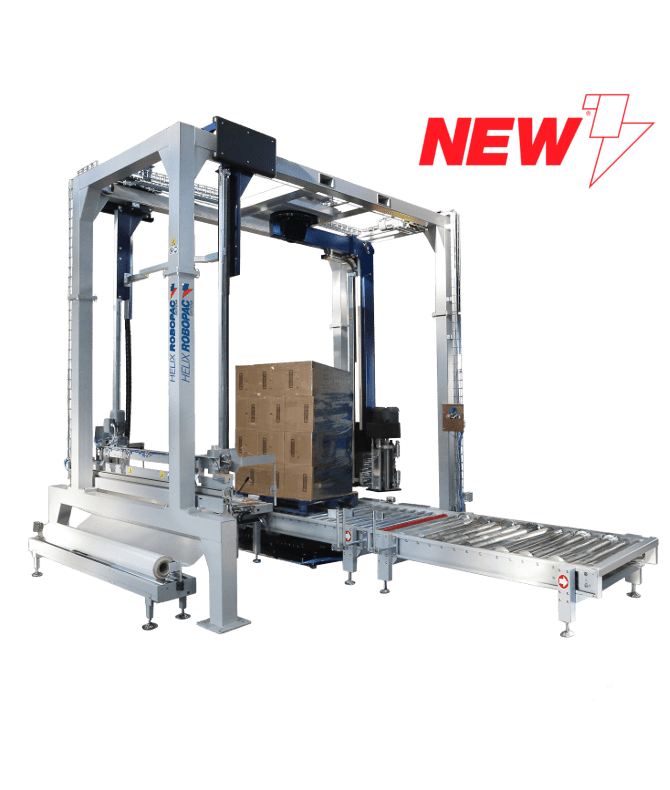

ROBOPAC SISTEMI HELIX 1 EVO Stretch Wrap

Automatic wrapping machine with rotating arm for average productivity.

The automatic machine with rotating arm for wrapping palletised loads with stretch film, it is particularly suitable for use in trade sectors where high production rates are required and for light products, easily deformable and unstable.

Thanks to the rotating arm technology, film application and load stabilisation are carried out with pallet stopped thus avoiding any risk of load falling, regardless of the arm rotation speed.

The modularity of the units composing it results in wide versatility of use , even with large pallets.

Robopac Sistemi – Al Thika Packaging LLC

Al Thika Packaging is an exclusive distributor of Robopac Sistemi in the Middle East. Since 1994 Al Thika has been supplying best automatic horizontal & vertical Stretch Wrapping machines for food & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.

PRE-STRETCH CARRIAGES

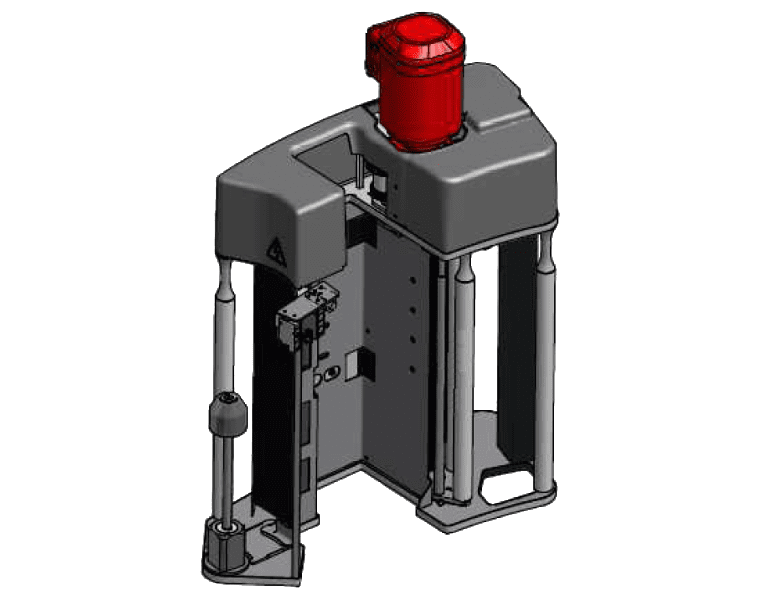

PGSM CARRIAGE – EVO

Pre-stretch carriage with single motorisation with standard provided ratios 150% – 208% -245%, which can be replaced manually thanks to optional kits for ratios from 80% to 344%

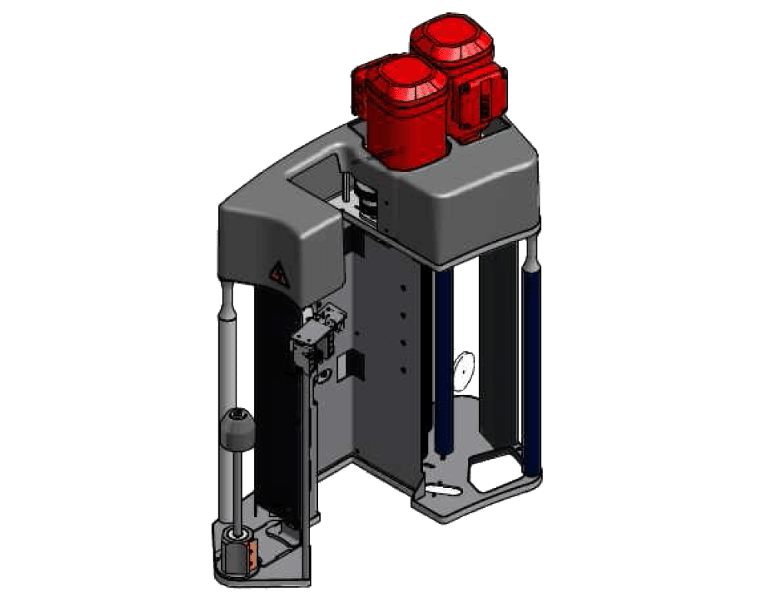

PGSA EVO CARRIAGE

Carriage with double independent motorisation for continuously varying pre-stretch from control panel 150% to 400% and apply up to 12 containment force values on the pallet.

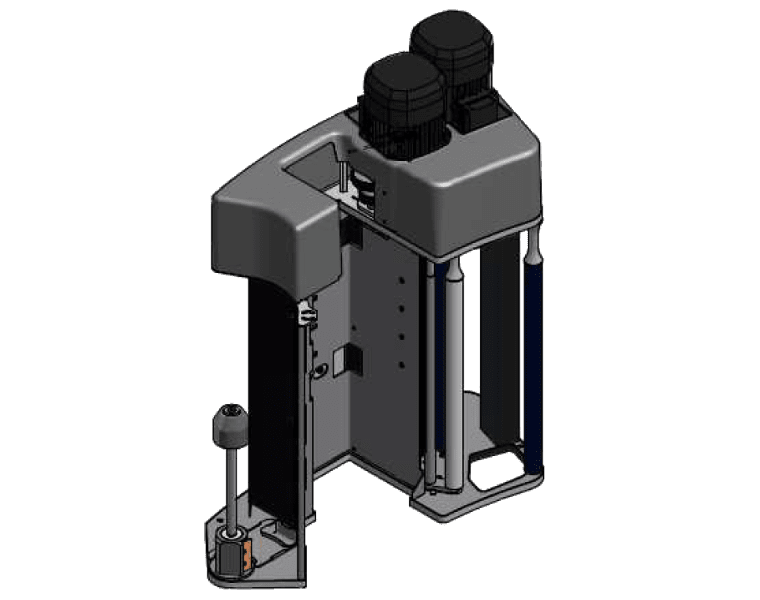

SCSP/2 EVO CARRIAGE

Carriage with double independent SSC motorisation for continuously varying pre-stretch from control panel 150% to 400% and apply up to 12 force containment values on the load.

CLAMPS

HOT PLATE SEALER

System to obtain perfect sealing of the stretch film

NIP&TUCK CLAMP

Clamp with wrapping film tail insertion

EVO PINCERS CLAMP

Standard pincers clamp with hot wire film cutting

EVO SPRING CLAMP

Optional new generations device for clamping, cutting and film sealing

MAIN OPTIONS

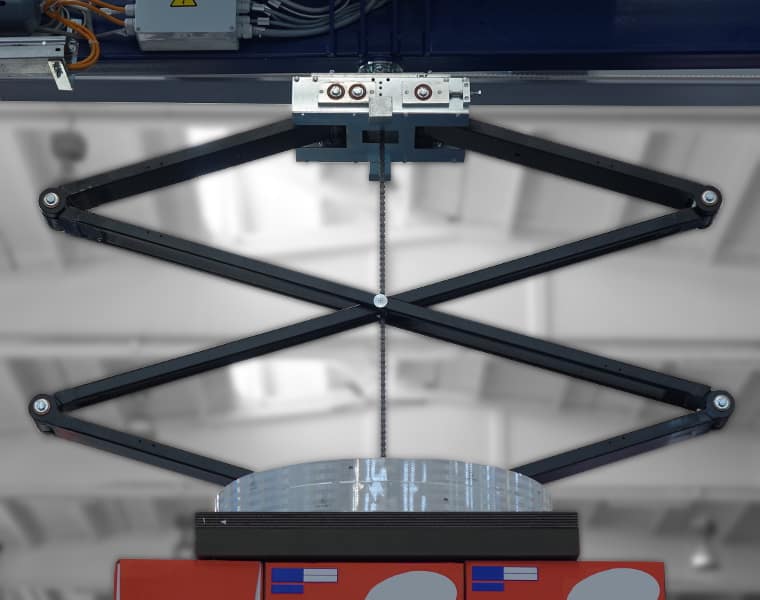

VERTICAL PRESSURE PLATEN

The device can be used with particularly unstable loads

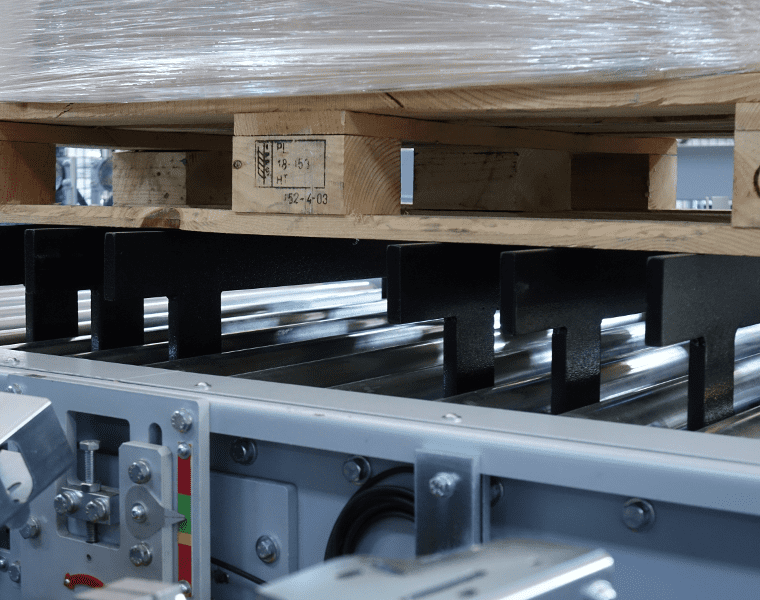

PALLET LIFTER

Pallet lifting system located under the conveyor in the machine centre

TOP COVER

Device for covering the upper side of the pallet

ROPING

Device for reducing the width of the wrapping film

VCA4 – CORNER APPLICATOR

Automatic corner applicator device to protect the load

DATA SHEET

| STANDARD TECHNICAL FEATURES | ||

| Pallet Dimensions min – max (*) | mm | 400×600 – 1220×1220 |

| Maximum pallet height | mm | 2000 |

| Output capacity (* *) | Pallet/h | 65 |

| Standard pre-stretch carriage | PGSM – single motorisation, fixed pre-stretch, optional kits for different pre-stretch ratios (manual replacement) | |

| Optional pre-stretch carriage | PGSA – Double independent motorisation, variable pre-stretch

SCSP/2 – Double independent SSC motorisation, variable pre-stretch |

|

| Pre-stretch ratio included | 161% – 208% – 269% | |

| ( *) Possibility of wrapping the half and quarter pallet | ||

| ( * *) In certain wrapping conditions and defined pallet sizes | ||

| STANDARD ELECTRICAL FEATURES | ||

| Power supply voltage | V | 380 – 400 – 415 ± 5% |

| Power supply frequency | Hz | 50 ± 1% |

| STANDARD PNEUMATIC FEATURES | ||

| Compressed air pressure | Bar | 6 ± 1 |

| REEL FEATURES | ||

| Film reel height | mm | 500 (Standard) – 750 (Optional) |

| Max reel diameter | mm | 250 |

| Reel cardboard height | mm | 510 (Standard) |

| Workable film thickness (***) | μm | 12 – 30 |

| TOP Film thickness | μm | 60 – 90 |

| (***) According to film quality | ||