Maximise Uptime: 9 Checkweighing Options Guaranteed to Ensure Flawless Transfers of Pharmaceutical Products

Dynamic checkweighers are used every day to provide the highest degree of weighing accuracy and ensure pharmaceutical products fully comply with GMPs (Good Manufacturing Practices) and worldwide regulations. However, smooth product transfers are essential to avoid unexpected line stoppages, prevent product backup and maximise productivity.

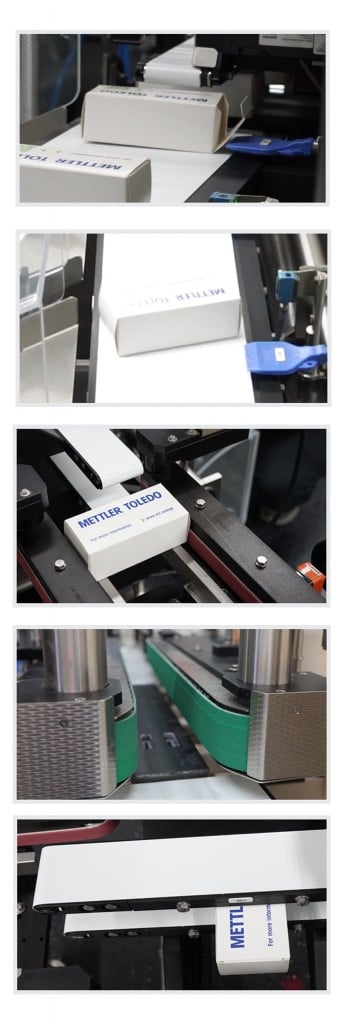

Check the video below to discover how Mettler Toledo checkweighers ensure flawless product transfers of a wide range of pharmaceutical applications, packaging types and sizes.

1. Detecting open flaps

See for yourself how photoelectric sensors help to avoid product backup by rejecting products with open flaps.

2. Detecting askew packages

Discover how askew package detection helps to ensure correct package orientation and allows the maximum skew that’s tolerable to be individually set and stored for each product setup.

3. Allowing flexible package alignment

Watch how the transversal adjustment option enables checkweighers to be adjusted transversally across the transport direction, reducing downtime by enabling fast and simple product changeovers.

4. Safely transporting unstable products

Find out how sidegrip conveyors can help to safely transport products that are prone to swaying or toppling over such as tall cans, jars and bottles.

5. Ensuring highly-precise and exact product transfers

See how a top and bottom belt conveyor provides the optimum solution for transferring products from the cartoner onto the checkweigher by preventing products skewing.

6. Ensuring rejected, non-conforming products are quarantined

Discover how the electro-mechanical locking function on catch bins enhances product safety by ensuring that access to rejected off-weight or contaminated products is restricted to authorised personnel.

7. Verifying rejected packages have entered the catch bin

Learn how the reject countercheck option allows 100% monitoring of the production flow and is capable of confirming that a package that should have been rejected is actually rejected.

8. Providing a local audit trail for complete process accountability

Discover how the audit trail function operates and provides process accountability by recording all activities and parameter changes.

9. Controlling checkweigher access

See for yourself how the login server provides facilities for creating and maintaining a database of all those who have access to the checkweigher.

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is an exclusive distributor of Mettler Toledo in the Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision product inspection systems for food and non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.