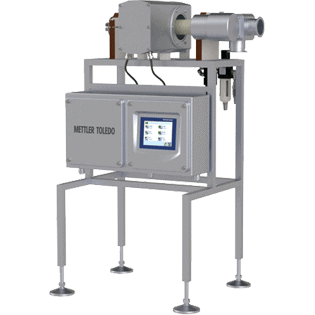

Safeline Pipeline Profile Metal Detector

Liquid/slurry/paste inspection

Metal detection systems controlled from a full-colour touchscreen operator interface for the inspection of pumped food products.

Maximum Sensitivity and Performance

Multiple ultra high tuned frequencies with enhanced noise and vibration immunity deliver exceptional sensitivity to consistently detect more metal.

Simple to Use and Robust Detector Design

Proven reliability. Intuitive, easy to use icon driven touchscreen. Finished in bead blast SS & sealed to IP66 for washdown applications.

Maximum Uptime

Condition monitoring and predictive analytics ensure maximum performance over time and allow a reduction in scheduled performance monitoring tests.

Features and Benefits

| Unrivalled sensitivity and stability | The maximum capacity to detect all metal contaminants with robust on-line stability for minimised false reject events. |

| Integrated reject systems | Effective rejection of all contaminants in liquids, pastes and slurries via a choice of reject valve options. |

| Designed for harsh environments | Stainless steel construction and sealing standards up to IP69K standard make L Series Profile pipeline detectors suitable for the harshest environments. |

| Performance validation software | Built-in performance validation software indicates when scheduled testing is due and assists QA staff by guiding them through step by step test routines. Systems can be designed to incorporate integrated test systems to aid compliance. |

| Easy to use | The intuitive Profile full colour operator touch screen provides easy set up and on-screen date analysis to aid manufacturing performance. |

| Compact design for easy line integration | Space saving design incorporating patented ZMFZ technology ensures installation can take place in situations where line length is extremely restricted. This also helps to reduce product creaming. |

| Built-in condition monitoring | Constant analysis of the detection coil and electronics systems provide advanced warning of potential problems prior to failure enabling planned maintenance routines to take place. |

| Connectivity options | Can be provided with an integral Ethernet adapter enabling connection to all external data collection devices and factory management systems. |

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the exclusive distributor of Mettler Toledo in the Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision product inspection systems for food and non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Pakistan, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.