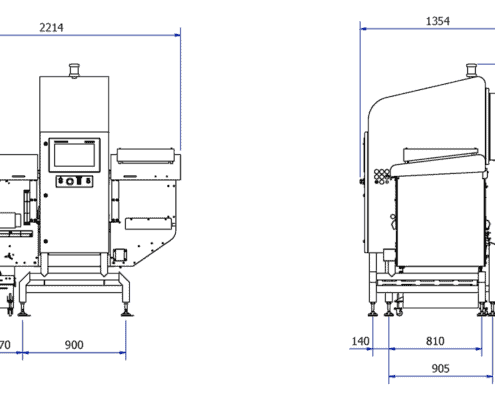

X36 Series X-ray Bulk product inspection

Loose product inspection by Mettler Toledo X-ray

Innovative Bulk Solution

Designed for loose bulk-flow food products, the X36 Series Bulk x-ray system offers outstanding contaminant detection before further value is added to the product, saving costs.

Minimising Product Waste

A choice of reject devices, from multiple scoop to air blast nozzles, offers a range of solutions depending on the application needs.

Reduced Running Costs

The advanced detector technology enables lower power x-ray generation offering reduced power consumption and running costs.

Hygienic Design

Class-leading hygienic design following GMP, NFS and EHEDG principles with IP69 as standard and an innovative design enabling full cleaning access.

X36 Series Bulk Variant Specification Table

| Casing Material | Stainless Steel |

| Ingress Protection | Full IP69 high pressure wash-down protection |

| Conveyor Speed | Typical line speeds 20-60 m/min |

| Infeed Options | Flexible infeed: Hopper or end-fed option |

| Throughput Rate | Typical throughput rates of up to 14,000 kg/hour |

| Maximum Product Layer | 550mm (W) x 30mm (H), dependent on product |

| Screen Display | 15.6” TFT (16:9 aspect ratio) |

| Operating Temperature | 5 – 40°C |

| Pneumatic Supply | Minimum 6 Bar(g) clean air supply required |

| Belt Tracking | Automatic pneumatic tracking and tensioning |

| X-ray Detector | 0.8mm diodes, 600mm width |

| X-ray Generator | 100W, 84kV, 1.2mA Beryllium |

| X-ray Emissions | < 1uSv/hr |

| Reject Type | Six lane scoops or seven lane air-blast options |

| System Conveyor | FDA and EU food use approved TPU conveyor belt |

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the main distributor of Mettler Toledo in Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision inspection systems in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.