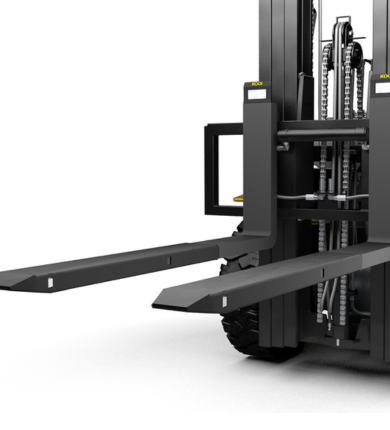

Hydraulic ReachForks

Hydraulic extendable forklift forks are designed to improve the functionality and efficiency of forklifts. The forks can be extended and retracted, allowing the operator to always adequately support pallets and or move pallets further away from the forklift over a certain distance.

| Minimum operating pressure | Provide sufficient support for various pallet types, reducing the risk of dropped loads |

| Efficiency in Time | Saves 40% of the time when loading and unloading trucks |

| Saving Costs | Achieves a time savings of at least 27%, it can further reduce time by up to 37%. |

| Forklift / Truck Driver Satisfaction | Damage-free transfers, enjoyable and smooth operation |

| Productivity / Work Flow | Telescopic forklift forks improve productivity in all applicationsimprove productivity in all applications |

| Space Saving | Telescopic forklift forks improve productivity in all applications, maximizing storage and operational efficiency. |

Industries: E-commerce | Logistics | Cosmetics | Pharmaceutical | Perfumes

KOOI® ROLLERFORKS

These specialised forks are designed with integrated rollers, enabling the easy handling of pallet-less shipments.

| Time-Saving | RollerForks can quickly unload containers since the slipsheets are on the floor, allowing the RollerForks to easily “scoop” them up by rolling underneath. |

| Space Saving | When a container needs to be loaded or unloaded, there’s no need to disconnect the RollerForks to switch to standard forks |

| Ergonomic | The RollerForks can be easily positioned under the slipsheet with the tips slightly tilted forward. |

| Increase Safety | RollerForks are safer to use compared to a push-pull attachment because RollerForks function similarly to standard forks with integrated rollers. |

| Productivity / Flow | RollerForks load and unload faster than push/pull attachments since they don't require a gripper function or pulling, increasing container handling efficiency. |

| Reducing Costs | RollerForks are similar in weight to standard forks, eliminating the need for a heavier forklift, unlike the costlier and higher-maintenance push-pull attachment. |

Industries: E-commerce | logistics | Cosmetics | Pharmaceutical | Perfumes

Manual Extendable ReachForks

Manual extendable forklift forks like the KOOI®’s are designed for various applications that require handling goods and pallets of different lengths.

|

Secure assembly |

European and International regulations (EN 1005-2, ISO 11228-1) state that a load of 23-25 kg (depending on the lifting method) is the maximum allowable weight. A fork extension tube at a length of 1500 mm. |

| Efficiency in Time | There’s no longer a need to assemble and disassemble individual sleeves, which saves significant time. |

|

Ergonomic to operate |

The manual extension forks extend by moving the release lever sideways, with no need for locking as there are no loose or self-locking parts. |

|

Productivity / Flow |

To eliminate the delays caused by add-on sleeves, the KOOI® manual ReachForks are ideal because the forks’ “extension” is always present on the forklift. |

Industries: E-commerce | logistics | Cosmetics | Pharmaceutical | Perfumes

Rollerized Tine Extenders

Rollerized Tine Extenders (RTE) are used in aviation to streamline the handling and transfer of air cargo. They facilitate smooth, efficient movement of cargo pallets and containers into and out of aircraft, minimizing physical strain and reducing the risk of damage to sensitive good

| Protection | High-strength steel construction with powder-coated protection |

| Weight capacity | Capacity of up to 10,000 kg |

| Easy | No hydraulic or special equipment is needed |

| Length | Available in various lengths |

Industries: Aviation

Stationary Pallet Changer

The Advantages of KOOI® Stationary Pallet Changer

| Increased Safety | The stationary towing unit is standard equipped with a warning buzzer and flashing light and can also be equipped with various other safety features. |

| Efficiency in Time | Changing pallets takes 30 seconds. This cycle time excludes the supply and removal of pallets. |

| Ergonomics | The operation can be from the forklift or two-handed operation, etc. |

| Cost Saving | Due to plastic pallet cost, they are often swapped out for transport outside the production area. |

| Productivity | Automatic pallet changing. Pallet dispensers can supply and remove pallets, such as wooden or plastic pallets. |

Stationary Push-Pull Installation

By placing the products on slip sheets with a hygienic pallet as the base during production, they can be pulled with a Stationary Push/Pull as a complete package from one pallet to another upon leaving the production area.

- Transfer goods using slip-sheets.

- Minimize risk of product damage.

- Ensure a quick pallet transfer process.

- No rotation of goods.

- Eliminate the need of manual handling.