Tinytag View 2 — TV-4501

The TV-4501 has an unobtrusive grey case and monitors temperatures from -25 to +50°C and relative humidity from 0 to 100% using built-in sensors. The coated RH sensor offers good resistance to moisture and condensation. Like the rest of the View 2 range, this accurate and reliable unit has a display providing a visual readout. This logger requires Tinytag Explorer software and a USB cable (CAB-0007-USB).

| Environment | Indoor |

| Measurement | -25 to +50°C/0 to 100% RH |

| Key Features | USB | Splashproof| |

Industries: Fruit & Vegetables | Dry Fruits | Meat & Poultry | Bakery & Confectionery | E-commerce | Dairy | Logistics | Warehousing | Beverage | Pharmaceutical | Seafood | Ready Meal

Typhoon Optical Sorter

Typhoon is an optical sorting machine with the highest resolution cameras to examine the product on the conveyor belt. The system is dedicated to checking the food products in pulpy or liquid form such as fruit pulp, crushed or extruded tomatoes, or pulpy diced fruit and tomatoes.

| Technology | LED pulsed light with CCD Camera |

| Optical resolution | 0,5×0,5 mm |

| Number of Extractor Nozzles | Ranges from 25-176 |

Industries: Fruit & Vegetables | Dry Fruits

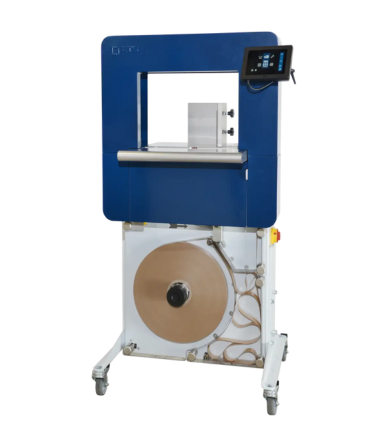

US 2000 AD Banding Machine

The US-2000 AD with ultrasonic technology is a powerful, proven and universally applicable banding machine. It is extremely robust, low-maintenance and energy-efficient.

Options

Industries: E-commerce | Logistics | Food | Dry Fruits | Fruit & Vegetables | Dairy | Cosmetics | Seafood | Pharmaceutical | Non-Food

US-3000 banding machine that sets new benchmarks

The patented ultrasonic welding technology makes the US-3000 the most powerful, reliable and energy-efficient banding machine on the market. It consumes 98% less energy than a shrinking machine and ensures consistent welding quality even in extremely cold, dusty or humid conditions. The US-3000 requires no preheating and generates no heat during welding that can damage sensitive products.

Industries: E-commerce | Logistics | Food | Dry Fruits | Fruit & Vegetables | Dairy | Cosmetics | Seafood | Pharmaceutical | Non-Food

V11 Label Inspection System

Adaptable, integrable, cost-effective vision system.

This flexible label inspection solution reliably inspects oriented products from the sides or top for label data and quality defects. It can be easily integrated into existing production lines utilising smart cameras, lighting, and software.| Reading Devices | Smart Camera |

| Number of Reading Devices | 4 |

| Max Camera Field of View | 95 x 71 mm |

| Camera Inspection Area | Side Top |

| Label Quality Inspection | Graphical ID Label Placement Label Skew Label Wrinkles |

| Label Data Inspection | 1D/2D Barcode Alpha Numeric |

Industries: Agriculture | Bakery | Bulk Chemical | Bulk Foods | Cosmetics | Confectionery | Dairy | Meat & Poultry | Nutraceuticals | Oil & Fat | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood |

V15 Label Inspection 360° System

Adaptable, integrable, cost-effective vision system.

This flexible label inspection solution reliably inspects oriented products from the sides or top for label data and quality defects. It can be easily integrated into existing production lines utilising smart cameras, lighting, and software.| Reading Devices | Smart Camera |

| Number of Reading Devices | 4 |

| Max Camera Field of View | 95 x 71 mm |

| Camera Inspection Area | Side Top |

| Label Quality Inspection | Graphical ID Label Placement Label Skew Label Wrinkles |

| Label Data Inspection | 1D/2D Barcode Alpha Numeric |

Industries: Agriculture | Bakery | Bulk Chemical | Bulk Foods | Cosmetics | Confectionery | Dairy | Meat & Poultry | Nutraceuticals | Oil & Fat | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood |

V31 Vision Inspection System

Adaptable, integrable, cost-effective vision system.

Advanced package and label inspection of oriented products by V31 vision inspection system. The flexible system includes a rapid installation frame and product tracking for support of up to six cameras and customised lighting| Reading Devices | PC-Based Camera |

| Number of Reading Devices | 6 |

| Max Camera Field of View | 300 x 200 mm |

| Camera Inspection Area | Side Top |

| Label Quality Inspection | Graphical ID Label Placement Label Skew Label Wrinkles |

| Label Data Inspection | 1D/2D Barcode Alpha Numeric |

Industries: Agriculture | Bakery | Bulk Chemical | Bulk Foods | Cosmetics | Confectionery | Dairy | Meat & Poultry | Nutraceuticals | Oil & Fat | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood |

Weighing scale IWS 2000

With the intelligent IWS 2000 levelling scale, you can optimise the giveaway of the goods to be packed using dynamic weight limit control.

| Weighing platform - Sizes | 200 x 300 mm 300 x 400 mm |

| Power supply | Power supply unit 24V |

| Interface | WLAN 2.4GHz |

| Colour LCD touch display | 3,2 inch display |

Industries: Fruit & Vegetable

X12 X-ray Inspection System

Precise, Complete, and Ultimate Detection by X12 X-ray.

X12 high-performance x-ray inspection system that delivers improved product quality and increased product safety. The X12 system is the perfect solution for small-medium food and pharmaceutical products.| X-ray Beams | Single vertical beam |

| X-ray Generator | 100 W, up to 84 kV, up to 3.3 mA Glass Tube 150 W, up to 85 kV, up to 3.0 mA Glass Tube |

| Diode Size | 0.4 mm |

| Max Throughput | 300 ppm |

Industries: Bakery | Confectionery | Dairy | Bulk Chemical | Meat & Poultry | Ready Meals | Snack Foods | Seafood | Oil & Fat | Pet Food | Pharma | Nutraceuticals

X16 X-ray Inspection System

Safe, Accurate, and Complete Inspection.

The X16 system is the prime solution for medium-large food, and pharmaceutical products. This innovative x-ray inspection system delivers enhanced product quality and improved product safety| X-ray Beams | Single vertical beam |

| X-ray Generator | 100 W, up to 84 kV, up to 3.3 mA Glass Tube 420 W, up to 84 kV, up to 5.0 mA Glass Tube |

| Diode Size | 0.4 mm |

| Max Throughput | 1000 ppm |

Industries: Bakery | Bulk Chemical | Cosmetics | Confectionery | Dairy | Meat & Poultry | Nutraceuticals | Oil & Fat | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood |

X32 X-ray Inspection System

Precise, Complete, and Ultimate Detection by X32 X-ray.

X32 an advanced x-ray inspection system available in standard and custom configurations, with single or multi-lane capabilities and integrity checks for outstanding detection performance.| X-ray Beams | Single vertical beam |

| X-ray Generator | 100 W, up to 84 kV, up to 3.3 mA Beryllium Tube |

| Diode Size | 0.4 mm |

| Max Throughput | 1000 ppm |

Industries: Bakery | Bulk Chemical | Confectionery | Dairy | Meat & Poultry | Nutraceuticals | Oil & Fat | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood |