S560 - L-seal Hood Packer

Manual Shrink Wrapper

The S560 manual l-sealing machine gives an output ranging up to 300 packs/hour.| Sealing area | 560 x 430 mm |

| Maximum pack height | 260 mm |

| Average output up to | 300 pph ** |

Industries: Bakery | Confectionery | Dairy | Cosmetics | Automotive | Ready Meals | Snack Foods | Pet Food | E-commerce | Logistics

S560NA - L-Seal Hood Packer

Manual Shrink Wrapper

The Smipack S560NA series gives an output ranging up to 900 packs/hour.| Sealing area | 560 x 430 mm |

| Maximum pack height | 260 mm |

| Average output up to | 900 pph ** |

Industries: Bakery | Confectionery | Dairy | Cosmetics | Automotive | Ready Meals | Snack Foods | Pet Food | E-commerce | Logistics

S870 - L-Seal Hood Packer

Manual Shrink Wrapper

The S870 L-sealer for sealing and shrinking with outputs rang up to 300 packs/hour.| Sealing area | 870 x 620 mm |

| Maximum pack height | 310 mm |

| Average output up to | 300pph ** |

Industries: Bakery | Confectionery | Cosmetics | Automotive | Ready Meals | Snack Foods | Pet Food | E-commerce | Logistics

Single Clamp “FS 2200” Pallet Inverter

Free standing 180° inverter with single clamping table. Loaded and relocatable by forklift truck. With a 2 tonne capacity the FS Inverter is available in 3 standard jaw opening sizes with levers, push-button, remote or automated controls, or it can be built entirely to your specification.

Options

There are a number of control options including manual push button, fully automatic and remote control.

Industries: E-commerce | Logistics | Food | Dry Fruits | Fruit & Vegetables | Dairy | Cosmetics | Seafood | Pharmaceutical | Non-Food

SL 45 - L-Seal Hood Packer

Manual Shrink Wrapper

The SL 45 L-sealing hood packers give outputs ranging up to 300 packs/hour.| Sealing area | 410x250 |

| Maximum pack height | 210 mm |

| Average output up to | 300 pph ** |

Industries: Bakery | Confectionery | Dairy | Cosmetics | Automotive | Ready Meals | Snack Foods | Pet Food | E-commerce | Logistics

Stationary Pallet Changer

The Advantages of KOOI® Stationary Pallet Changer

| Increased Safety | The stationary towing unit is standard equipped with a warning buzzer and flashing light and can also be equipped with various other safety features. |

| Efficiency in Time | Changing pallets takes 30 seconds. This cycle time excludes the supply and removal of pallets. |

| Ergonomics | The operation can be from the forklift or two-handed operation, etc. |

| Cost Saving | Due to plastic pallet cost, they are often swapped out for transport outside the production area. |

| Productivity | Automatic pallet changing. Pallet dispensers can supply and remove pallets, such as wooden or plastic pallets. |

Stationary Push-Pull Installation

By placing the products on slip sheets with a hygienic pallet as the base during production, they can be pulled with a Stationary Push/Pull as a complete package from one pallet to another upon leaving the production area.

- Transfer goods using slip-sheets.

- Minimize risk of product damage.

- Ensure a quick pallet transfer process.

- No rotation of goods.

- Eliminate the need of manual handling.

Strapping Tool ZP93A & ZP97A

ZP93B & ZP97A Battery Powered Automatic PET & PP Combination Strapping Tool.

| ZP97A | Max. tension 400 KGS ( 4000N) |

| ZP93B | Max. tension 250 KGS ( 2500N) |

| Battery | 18V Li-Ion battery |

Industries: Bakery | Confectionery | Dairy | Cosmetics | Automotive | Ready Meals | Snack Foods | Pet Food | E-commerce | Logistics

T450 - Shrink Tunnel

Shrink Tunnel for Modular L-sealing machines

Compared to the traditional L-sealers, the FP series provides higher outputs as well as the possibility of using Polyethylene film, besides the traditional shrink films, and includes different models for outputs ranging up to 3600 packs/hour.| Installed Power | 8000 W |

| Maximum pack height | 230 mm |

| Speed of conveyors | 2 - 14,5 m/min |

Industries: Bakery & Confectionery | Dairy | Fruit & Vegetables | Seafood | Meat & Poultry | Non-Food | Laundry | Household Products | Toys | Cosmetics | Pharmaceutical | Logistic | Co-packers | E-commerce

Technoplat 2000

Automatic wrapping station

Technoplat 2000 is a high-performance, highly automated wrapping station for an end-of-line packaging.| Plate diameter | 1800mm |

| Max load weight | 1500kg |

| Turntable speed | 5÷15 rpm |

| Maximum product dimensions (LxW) | 1200x1000mm |

| Forklifting | front and rear |

Industries: Logistics | Furniture | Paper | Agriculture | Bakery | Dry Food | Bulk Foods | Cosmetics | Confectionery | Dairy | Meat & Poultry | Chemical | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood | Non-Food

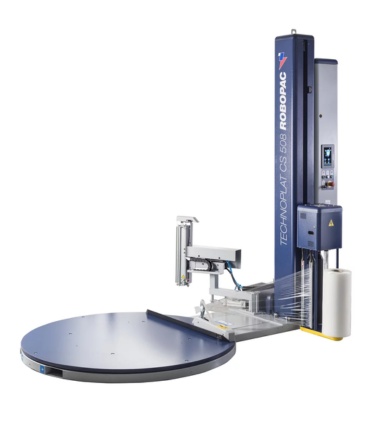

Technoplat CS/CW

Turntable wrapping machines with clamping, cutting and film spreading or welding system

Technoplat CS and CW are automatic wrapping machines and represent the innovative solution to fully automatic pallet wrapping.| Turntable diameter | (mm) 1650 std. 1800 opt. |

| Max load weight | (kg) 2000 std. 2500 opt. |

| Turntable speed | (rpm) 5÷12 |

| Maximum product dimensions (LxW) | (mm) 1000x1200 std. 1200x1200 opt. |

| Forklifting | front and rear |

Industries: Logistics | Furniture | Paper | Agriculture | Bakery | Dry Food | Bulk Foods | Cosmetics | Confectionery | Dairy | Meat & Poultry | Chemical | Pet Food | Pharma |Ready Meals | Snack Foods | Seafood | Non-Food

Technoplat PW

Turntable machine paper wrapping

The Technoplat PW is the Turntable for paper packaging from Robopac Machinery: an innovative and sustainable solution for final product packaging that uses environmentally friendly recyclable paper to ensure optimal protection without compromising environmental impact.| Productivity | Up to 30 pallet/h |

| Max load weight | (kg/lb) 2000 std / 2500 opt / 4409 std / 5512 opt |

| Maximum product height | (mm/in) 2200 std 2400-2800-3100 opt / 86 std 94-110-122 opt |

| Forklifting | front and rear |

| Paper consumption | (kg/lb) 0,6÷1,2 / 13÷26 ** |

Industries: Logistics | Paper | Agriculture | Bakery | Dry Food | Bulk Foods | Cosmetics | Pet Food | Pharma |Ready Meals | Snack Foods | Non-Food