Hot Melt Adhesive by Bostik – Kizen industrial glue

Hot melt and hot melt pressure sensitive adhesive for packaging, sealing and labeling

KIZEN hot melt adhesives for packaging, case & box folding, carton sealing, tray forming, consumer goods and bag manufacturing. The new generation hot melt glue from Bostik breaks the face-to-face existing so far between EVA adhesive and metallocenes, placing itself in an intermediate price range, but which in the long term and with convincing studies, represents the greatest savings in materials and machine downtime due to applicator carbonisation. Hotmelt industrial food grade adhesive is ideal for food and beverage industries.

Bostik is a leading global adhesive (glue) specialist in construction, consumer and industrial markets. For more than a century, it has been developing innovative sealing and bonding solutions that are smarter and more adaptive to the forces that shape daily lives. From cradle to grave, from home to office, Bostik’s smart industrial food grade adhesives can be found everywhere.

Hot Melt & Hot Melt Pressure Sensitive Adhesive for Advanced Packaging

Bostik adhesive solutions are applied in many consumer goods. The platform “Advanced Packaging” is specialised in developing innovative adhesives for modern packaging applications. These innovative solutions reduce cost-in-use, improve sustainability and increase operational efficiencies.

Bostik’s Hot Melt and Hot Melt Pressure Sensitive adhesives products meet the needs of even the most demanding and challenging applications. By improving manufacturing efficiencies and enhancing brands’ aesthetics, these tapes and label adhesive products also meet the needs of our customers.

ADHESIVE SOLUTIONS FOR PACKAGING & CONSUMER GOODS

HOT MELT ADHESIVE FOR CARDBOARD PACKAGING

From rigid to flexible, Bostik’s packaging adhesives have got you covered

Case and carton seal adhesives for the packaging market offer the quality customers deserve and the value they expect.

Bostik’s case and carton seal adhesive products for the packaging market are flexible, strong and offer extraordinary thermal stability.

From freezer and general purpose to low application temperature and thermal stability, Bostik’s innovative formulas enable these case and carton seal adhesive products to maximise customers’ manufacturing efficiencies.

Cutting-edge knowledge in the packaging market

They have the right open and set times and are optimised to perform most efficiently for today’s rapid production requirements.

Bostik’s case and carton seal adhesive products are also designed to handle a wide range of end-use temperatures and have high performance on difficult-to-adhere to substrates.

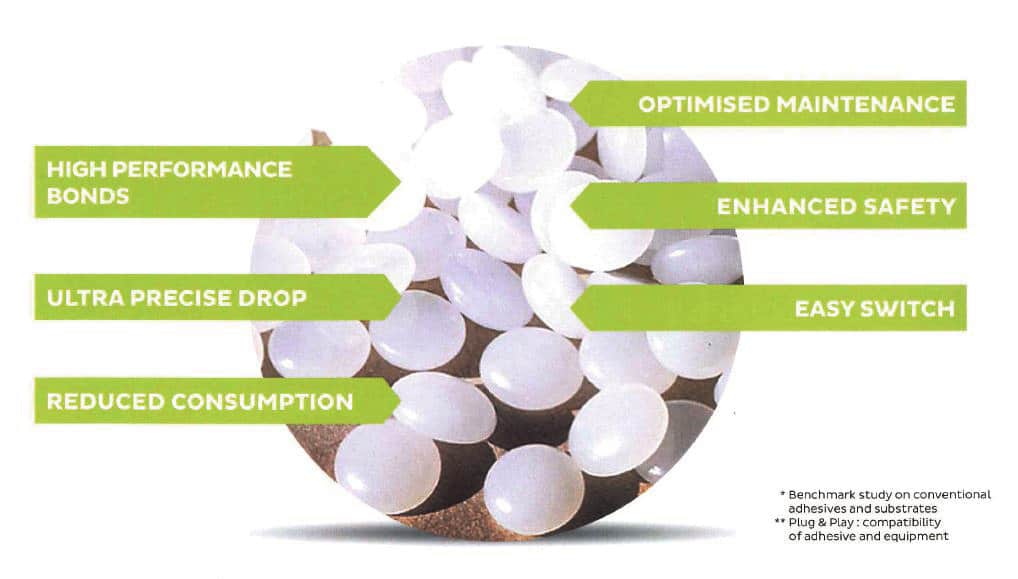

this new packaging adhesive technology offers:

- Fast set speed

- Broad processing window

- Good thermal stability

- Adhesion to many substrates, including highly recycled corrugated

INDUSTRIAL ADHESIVE FOR BOTTLE LABELLING

Exceeding your evolving needs, tape & label adhesives

Bostik bottle label adhesives ensure clean, efficient and stable machining for more efficient operation. Our bottle labelling solutions are suitable for use with glass, polyolefin, and food-grade plastic bottles such as PET.

We provide a truly versatile offering of technologies in this area, with products ranging in viscosity, longevity and strength of adhesion, pressure sensitivity, and functionality in both hot and cold environments. Overall, this allows you to choose from a wide selection of chemical formulations that cater to various factory environments, application processes and operation speeds.

Range of tape and label applications

Bostik’s versatile adhesives for the tape and label market meet the specific demands and requirements the ever-evolving market entails.

Bostik’s tape and label adhesive products meet the needs of even the most demanding and challenging applications. By improving manufacturing efficiencies and enhancing brands’ aesthetics, these tapes and label adhesive products also meet the needs of our customers.

From construction tape adhesives and masking tape adhesives to freezer label adhesives and removable label adhesives, Bostik’s products are flexible and versatile. Whether customers want an off-the-shelf product for tape or label applications or need one customised to their specific requirements, Bostik works with them every step along the way to ensure satisfaction.

KIZEN ADHESIVE OVERVIEW

Cutting edge adhesive solutions, driven by Arkema expertise.

From a unique innovative hotmelt technology, KIZEN has been designed for ease of use and strong bond performance for cardboard packaging, board lamination, paper bag sealing, tissue sealing, tray forming, envelope closing, box folding. All KIZEN products are packaged in 12 kilo bags.

–KIZEN FORCE: “One fits all”, one of the most versatile Hot Melt Adhesive with high bonding on difficult substrates.

–KIZEN HEAT: Dedicated to hot filling conditions and tropical countries.

–KIZEN ICE: Devoted to extremely difficult substrates and deep freeze goods (-20°C).

BOSTIK – AL THIKA PACKAGING LLC

Al Thika Packaging is the exclusive distributor of Bostik company in the Middle East. Since 1994 Al Thika has been supplying a wide range of hot melt adhesive, industrial food grade hot melt glue for food and non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Kuwait, Bahrain, Oman and the many other Gulf countries.