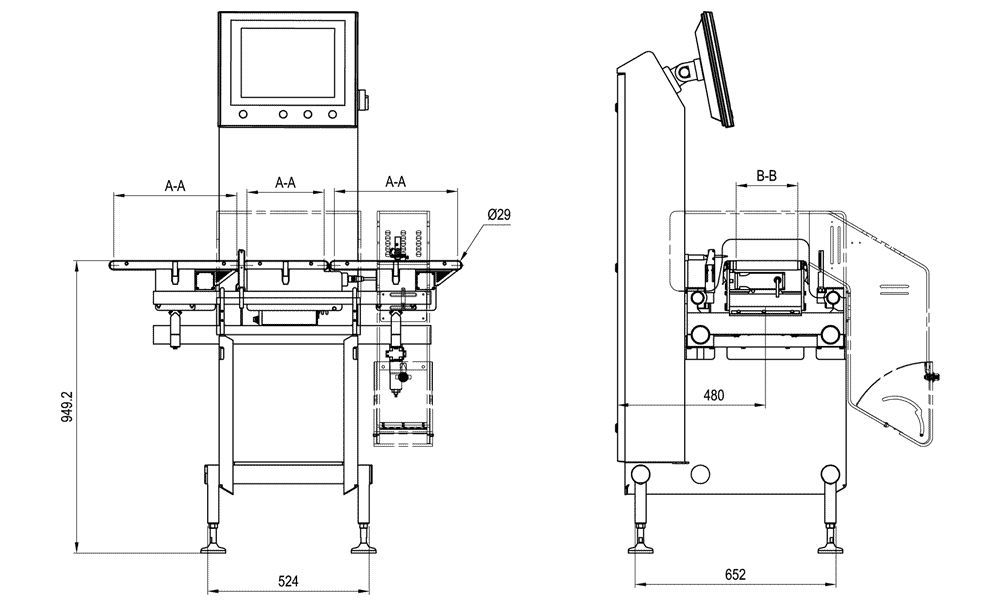

C35 AdvancedLine Washdown Checkweigher System

Hygienic solutions checkweighing machine by Mettler Toledo

Precision and Versatility.

Built for harsh environments, the Mettler Toledo C35 checkweigher combines uncompromising precision at fast speeds with a stable and resilient system design which, including the HMI, is fully IP69 rated and proven resistant to most caustic detergents and high-pressure cleaning.

Highest Accuracy in Harsh Environments

Highest accuracy including MID certification helps to comply with local weighing regulations and reduce costly product waste.

Hygienic Design for Easy Cleaning

The system provides easy access for cleaning and sloped surfaces throughout to prevent liquid retention and discourage bacterial contamination.

Resilient in Harsh Environments

The entire system, including the HMI, is IP69 rated and proven resistant to most caustic detergents, disinfectants, and high pressure cleaning.

| Throughput | 250 ppm |

| HMI | 15″ |

| Weighing Range | 25 g – 7 000 g |

| Preferences | Multi-lane |

| Product Width | 400 mm |

| Hygienic Requirement | High Pressure (IP69) |

| Maximum Product Weight | 7 kg |

| Transport Height | 750 mm – 1 100 mm (± 50 mm) |

| Combination Options | Metal Detection |

| Industry | Food |

| IP Rating | IP 69 |

| Accuracy | from ±0.2 g |

| Production Environment | Wet Harsh |

| Weighing Technology (Load Cell) | EMFR |

| Customization Options | Bespoke handling OEM |

| Approval | Weights & measures design approval for official verification (MID certifiable) |

| Weighing Combinations | Contamination Detection |

Exceptional Weighing Precision

Checkweighing which optimised for fast line speeds even for lightweight products, highly adaptable to meet customer requirements with over 160 software and mechanical options. A throughput max of 250 packs per minute and a weighing range from 25g to 7kg.

Reduced Downtime with Fast Maintenance

Intuitive and fast release or complete removal of the conveyor belts supports customer specific hygiene and cleaning requirements. The driving unit can also be dismounted and changed easily for maintenance purposes, keeping downtime to a minimum.

Failsafe Operation Prevents User Errors

The C35 Mettler Toledo checkweigher system supports failsafe operation with error-safe reassembly of the conveyors. Rollers from the in-and outfeed conveyors cannot be accidentally added to the weighing conveyor. Self-adjusting, elastic belts remove the need for straining upon reassembly.

Food Standards Compliance Support

The conveyor materials that are in direct food contact fully comply with Regulation (EC) 1935/2004, Regulation (EU) 10/2011) and FDA regulations governing the same.

Intuitive Operation with 15″ Touchscreen

The open design of the C35 checkweighing system features a large, 15-inch colour touchscreen at the rear to display all key weight, production, and configuration data in over 30 languages, and is resistant to most caustic detergents and pressure cleaning without requiring a cover.

Support for Data Collection Conformity

Open interfaces such as OPC UA, PackML, and Fieldbus enable IoT/Industry 4.0 initiatives so that production data can be accessed, analysed, and controlled anytime and anywhere. Optional integration with ProdX, METTLER TOLEDO’s Data Management Software.

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the exclusive distributor of Mettler Toledo company in the Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision product inspection systems for food and non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Pakistan, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.