DAIRY PACKAGING INSPECTION CODING MACHINERY SOLUTIONS

Al Thika Packaging provides a range of packaging machines and solutions specifically tailored for the dairy and cheese sector. The company’s machinery allows customers to combine traditional products with attractive packs that offer guaranteed presentation and superior preservation. The systems are designed to meet the unique needs of the dairy industry, delivering maximum efficiency for increased productivity, while providing excellent results in terms of product quality, shelf life, food safety and cost saving. Al Thika Packaging also offers advanced labelling solutions for dairy & cheese applications, enabling full traceability throughout the production processes. With ULMA packaging, Markem Imaje coding and labelling, Mettler Toledo product inspection, Robopac stretch wrapping and Tinytag data loggers, we are the only supplier who can cater to all your requirements from single machines, to installing a complete line.

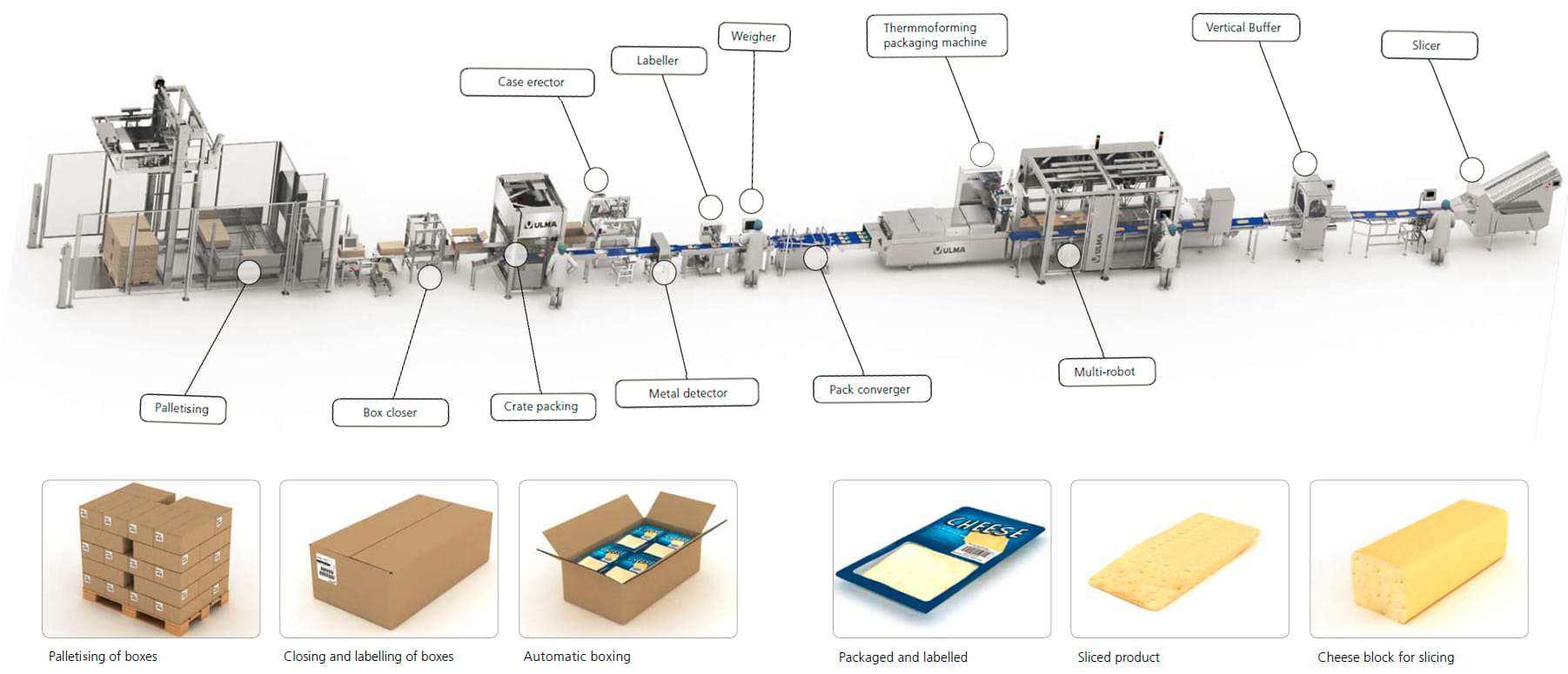

Dairy Packaging machine solutions

ULMA Packaging

ULMA is offering complete solutions that include from the handling of the product from the airing to the handling area and to the final crate packing and palletising, passing through the packaging with the possibility of choosing from between four different packaging systems: Thermoforming, Traysealing, Horizontal Flow Pack (HFFS) and Vertical Flow Pack (VFFS).

Sustainable packaging solutions with a cardboard tray

THERMOFORMING

Sealing of trays formed by automatic machines called thermoformers. The internal cavity is formed, using a roll of film, where the product is placed and then it is sealed with another film that is also the cover.

- VACUUM

- MAP

- SKIN

TRAYSEALING

Sealing of preformed trays in automatic machines called traysealers. The trays can be foam or rigid.

- MAP

VERTICAL (Vertical Flow Pack)

The wrapping is done by vertical flow pack wrapping machines that form a tube of film around a product and create a longitudinal sealing along the pack and another two transversal ones.

This technology is completely hygienic with high production requirements where the product is vertically charged.

- MAP

FLOW PACK

Using a single roll of film, a tube of film is made around the product and three welds are made to seal the pack: two transversal ones and a longitudinal one.

- MAP

- FLOW-VAC®

- BDF® (Shrink Barrier Film)

- SHRINK

PRODUCT INSPECTION SYSTEMS FOR DAIRY

Metter Toledo Safeline & Garvens

Mettler Toledo provides in-line product inspection solutions for the dairy industry with Safeline metal detectors and x-ray inspection systems, Hi-Speed checkweighers, CI-Vision machine vision inspection systems. Our systems ensure perfect product presentation, verify package and label integrity, ensure weight range compliance, detect physical contaminants and inspect closed package contents.

SAFELINE X-RAY INSPECTION SYSTEMS

Safeline X-ray Product Inspection Solutions Enhance Product Safety and Quality Control

Mettler Toledo X-ray designed for high-speed multi-lane applications and able to detect contaminants as small as 0.8mm, such as glass, metal, mineral stone and high density plastic, ticked all the boxes.

SAFELINE METAL DETECTION

Industrial metal detectors for the dairy product processing and packaging industries

The Mettler Toledo metal detector detects products contaminated with the metal such as screws, metal shavings, staples, nails, filings or wire cuttings, which are then also ejected.

CHECKWEIGHER SOLUTIONS

The most comprehensive line of checkweighing solutions for the dairy industry

The Mettler Toledo checkweigher determines weights quickly and accurately, and any products with an incorrect weight are rejected.

DAIRY CODING & MARKING MACHINE

Laser coding, thermal transfer, print and apply printer

Markem Imaje provides the highest product availability, the lowest total cost of ownership (TCO), and 100% accurate, high-contrast prints, every time. Whether you are printing on flexible film, HDPE plastic or carton bricks, we have got you covered with the laser, hot melt, print & apply and laser technologies to meet the needs of your ever-changing market. Our eco-friendly solutions support your product, case and pallet coding needs, all while minimising operator errors with intuitive controls and our Colos software.

Temperature & Humidity data logger for dairy

Tinytag radio data loggers

Tinytag wireless temperature & humidity data loggers are used during the cheese & other dairy products production process from initial monitoring of freezers storing cultures, through cold storage and warehousing, to temperature controlled distribution. Effective monitoring ensures quality standards are maintained throughout the cold chain.

Pallet Stretch wrapping machine for dairy products

Robopac stretch wrap

Robopac line of semi-automatic and automatic pallet stretch wrapping machine combines technology, innovation and experience into products that deliver results you can depend on. We have the complete range of wrapping machines for full stainless and suitable up to 30° solution.

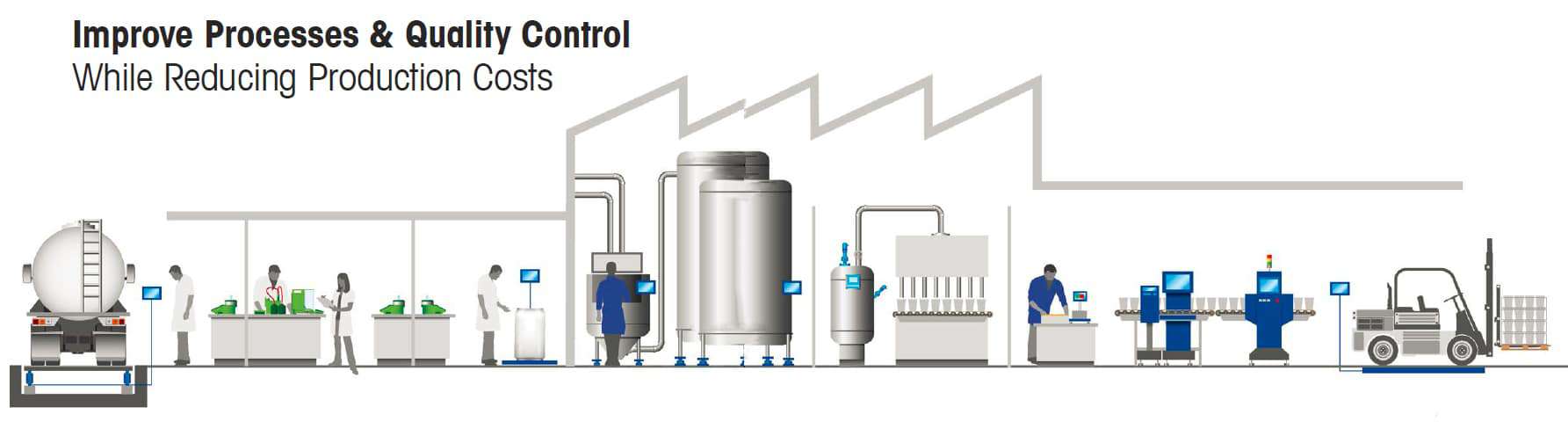

What are dairy machinery solutions and how can they improve production?

Dairy machinery solutions refer to advanced equipment designed specifically for the dairy industry, aimed at optimising production processes. These solutions include automated filling and sealing machines, inspection systems, stretch wrapping machinery, and coding equipment. By automating tasks, ensuring accuracy, enhancing product safety, and streamlining operations, these machinery solutions significantly boost production efficiency and output.

What role do inspection systems play in dairy production?

Inspection systems are crucial in maintaining product quality and safety in the dairy industry. These systems utilise advanced technologies, such as vision systems, to detect defects, foreign objects, and abnormalities in dairy products. By identifying and rejecting compromised products, inspection systems ensure that only high-quality and safe products reach the market, protecting both consumers and brand reputation.

How does stretch wrapping machinery optimise dairy production?

Stretch wrapping machinery securely wraps pallets of dairy products, providing stability during transportation and storage. By ensuring the integrity of pallet loads, this machinery prevents damage, product spoilage, and loss during handling. Additionally, the integration of intelligent controls and film tensioning systems enhances efficiency, reduces labour-intensive tasks, and streamlines the pallet wrapping process for improved productivity.

What advantages do coding machinery solutions offer in dairy production?

Coding machinery plays a vital role in dairy production by applying batch numbers, expiry dates, and barcodes to product packaging. These codes enable traceability, facilitate inventory management, and enhance consumer convenience. Advanced coding solutions offer high-speed and high-resolution printing capabilities, ensuring clear and legible codes on various packaging materials. Integration with data management systems further enhances efficiency and reduces errors in coding processes.

How can dairy machinery solutions contribute to cost savings for manufacturers?

Dairy machinery solutions optimize production processes, minimize waste, and reduce manual labour requirements. By automating tasks, improving accuracy, and streamlining operations, these solutions enhance overall efficiency and productivity. Increased output and reduced waste result in cost savings for dairy manufacturers, allowing them to achieve better resource utilisation and improved profitability.

Al Thika Packaging is an exclusive distributor of the world-renowned manufacturers of packaging, inspection, coding and wrapping machinery in the Middle East. Since 1994 Al Thika has been supplying machinery for food, beverages & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Kuwait, Bahrain, Oman and the many other Gulf countries.