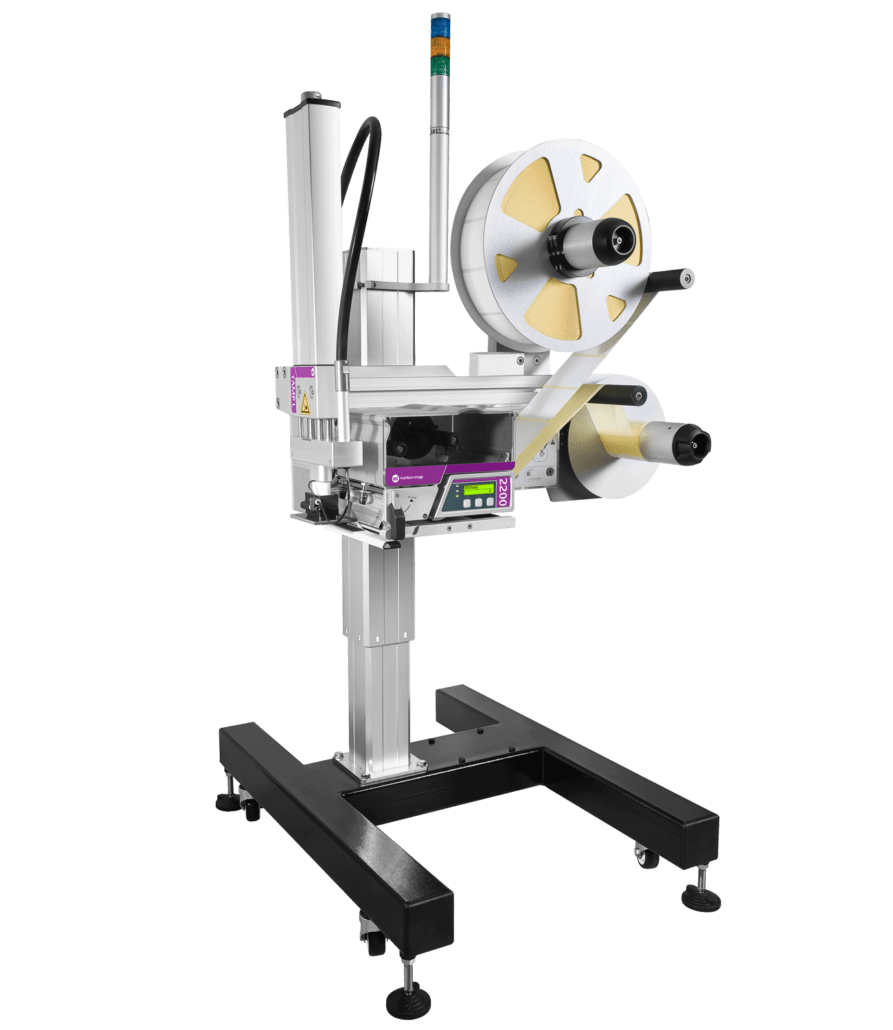

2200 Series print and apply barcode labeller

Case labeler by Markem-Imaje

The 2200 Series provides a flexible range of print and apply labeling solutions, from simple case labeling to high speed front of pack or multi side labeling.

The Markem-Imaje 2200 Series print and apply barcode labeller builds on a proven concept providing reliability, efficiency and ease of use with thousands of units installed in demanding 24/7 environments. The 2200 Series takes print and apply to the next stage of evolution, giving you a wide range of interchangeable applicators, optimised operational intervention and unparalleled application rate.

Material Type

Plastic Films | Corrugate

Industries

Confectionery | Personal Care | Pet Food | Dairy | Pharmaceuticals | Cosmetics | Food | Beverage

Technology

Print and Apply Labeling

Speed

High | Medium | Low

Efficient and reliable GS1 compliant solutions for all case and pack labelling requirements.

Your challenges

You are looking for a high-speed labeler that will improve product traceability and inventory control through reliable, consistent label application, reducing product recalls. You may have complex labeling requirements, such as front or pack, or varying product labeling demands from small batch operations. You require a labeler that is user-friendly, with reduced operational interventional to maximize production line availability and efficiency while minimizing the possibility of human error.

Markem-Imaje solutions

The 2200 Series features distinctive technologies that will help you to achieve a great cost of ownership through maximum production uptime, high performance, and minimum downtime. No more missing label or jams thanks to its consistent label application via optimized label path, automatic label tension and integrated pad label sensor. Choose among a wide range of interchangeable applicators best suited for each of your applications, minimising the need for line changes and expensive modifications.

Key benefits

The 2200 Series Case and Pack labeler efficiently maximises your uptime with several features that reduce line stoppages and downtime associated with media change. Able to print and apply with several types of applicators at up to 125 packs per minute, regardless of the complexity of the code, the 2200 Series provides faultless traceability with Compliant ANSI grade A/B codes, even at the highest application speeds. Designed to reduce operational errors, the CoLOS based Production Interface allows you to select your labels from either a local or remote data source enabling operators to visualize real production data in a large colour display.

Why you choose print and apply labeller

- Ability to print and apply at rates up to 125 packs per minute regardless of the data complexity or content.

- Simple media path allows operators to reload label and ribbon rolls in less than 40 seconds.

- 560 m ribbon and label rolls compared with the market standard of 450 m to reduce the line stoppages by 25%.

- Compliant ANSI grade A/B codes even at the highest application speed.

- CoLOS software solutions ensure product data integrity, central data management and easy connection to existing enterprise database.

- Designed to be over 95% recyclable.

Markem-Imaje – Al Thika Packaging LLC

Al Thika Packaging is the distributor of Markem-Imaje in the Middle East. Since 1994 Al Thika Packaging has been supplying traceability equipment, marking, coding printer and consumables for food, pharmaceuticals and beverage industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.