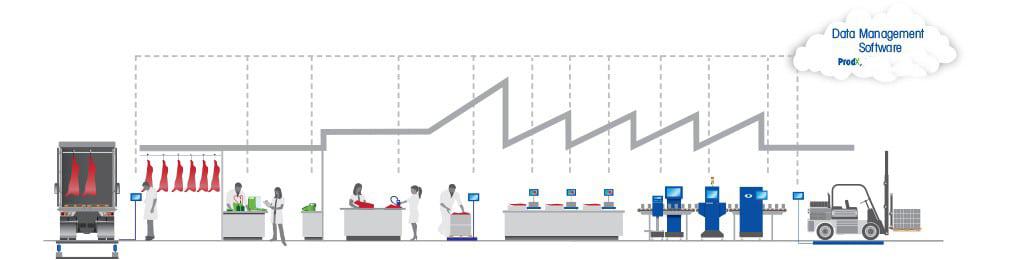

Machinery solutions for meat and poultry

To improve quality, safety and productivity

Al Thika Packaging is aware that the success of its clients depends on the quality of their products and protective packaging. We draw from more than 25 years of experience supplying packing machine, stretch wrapping machine, product inspection, coding printer weigh price labeller to guarantee our clients the highest quality solutions for the commercial success of your products and brands.

Meat and chicken packaging machine solutions

Packaging – MAP – SKIN – VACUUM

We offer the widest range of packaging solutions on the market for the meat & poultry sectors, from solutions for catering distribution to final retail distribution. We offer packaging solutions between different packaging systems: Vaccum Pack, Traysealer & flow pack wrapper, each with their unique ability to customise the package presentation and shelf-life needs of the product.

Product Inspection system Solutions

by Mettler Toledo

Cost pressure and short shelf life combined with complex regulatory requirements impact meat and poultry manufacturers. Packaging trends and market requirements for wider product variety add additional pressure. Mettler Toledo’s solutions are designed to make it easier to detect smaller contaminants, reduce product waste, minimise false rejects, maximise uptime and meet compliance needs.

Whatever your product format and material handling method at the designated critical control point – loose or bulk, pumped,

fresh, frozen, or packaged – we have a product inspection solution to meet your needs.

Foreign Body Detection and Rejection by Metal Detector

Wet products such as meat and poultry can be challenging for traditional metal detection technology. Our patented Profile Advantage system overcomes “product effect” to detect smaller irregular shaped contaminants, delivering enhanced brand protection. By virtually eliminating false rejects, operator efficiency is improved.

Automation of Quality Control Processes by X-Ray

Manually checking for missing products, damaged packaging, or under- and over-weight products can be a time consuming process.

Quality checks can be automated using X-ray inspection, checkweighing, or vision inspection technology to enhance production line efficiency.

Minimise Overfill to Reduce Waste by Checkweigher

Overfilling results in unnecessary product giveaway and leads to increased costs. Using a dynamic checkweighing system ensures each and every product is inspected to guard against under- or over-weight products and comply with weights and measures legislation.

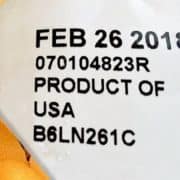

Coding and marking printer for meat and chicken

by Markem Imaje

Markem-Imaje provides the reliable coding that you need for all aspects of the meat and poultry industry. Whether you are printing best before dates, ingredients, logos or barcodes, Markem Imaje machines will produce the highest quality codes, even in your demanding environments. Powered by our intuitive CoLOS software, Markem-Imaje hot melt, print & apply and laser technologies will minimise operator errors while increasing your sustainability and reducing your total cost of ownership (TCO).

Thermal transfer printer

SmartDate Series deliver high quality printing on flexible packaging films, foils and labels for continuous and intermittent operations, at the fastest print and acceleration/deceleration speeds. They include multiple ribbon saving features.

Laser coding printer

Markem-Imaje Lasers can be useful in many scenarios. They can code on small areas on inked boxes or across multiple lanes of wide web flexible film where other methods cannot reach and can help you code effectively on glass or metal. Laser’s high contrast codes – which do not rub off or fade over time – can also ensure the lifetime traceability of your products and protect them from being counterfeited.

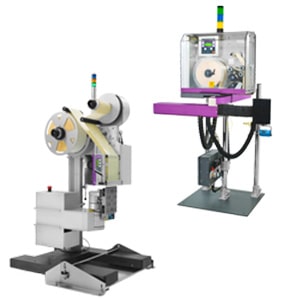

Print and apply labeling

Print and apply systems are used to identify pallets in increasingly automated environments. The system can be easily integrated into any production line. Outstanding printing quality and precise application result in excellent barcode reading in all distribution channels.

Large character high resolution piez

5400 and 5800 coders print codes and logos. Their Touch Dry® Hot Melt inks are solvent-free and environmentally friendly. Codes never bleed or fade, dry on contact and are 100% readable.

WEIGH PRICE LABELLER

By Espera

Espera is a worldwide leading manufacturer of weigh price labeller machine which is used in all kinds of food industries as well as in further processing industries. Espera’s outstanding portfolio always fulfils the requirements of the customers. Additionally, to machine technologies, Espera offers a huge range of software solutions for the producing industry.

Temperature & Humidity Data Logger

By Tiny Tag from Gemini data logger

Data loggers are used extensively in the meat and poultry industries where it is vital that temperatures are accurately maintained at specified levels and recorded for ongoing verification.

Data loggers are used in processing, cooking, pasteurisation, cooling and freezing. They are used throughout cold chain storage and distribution; in refrigerators, freezers and chilled display cabinets; and during sterilisation procedures and in industrial dishwashers.

Both standalone Tinytag data loggers and the Tinytag Radio Data Logging System are an effective solution for temperature and relative humidity monitoring in the meat and poultry industries, allowing conditions to be recorded, analysed and validated.

Standalone loggers record data which is downloaded via a USB cable to a PC for analysis. Radio loggers gather information automatically using wireless communications: the System consists of a receiver connected to a computer or LAN and a number of radio loggers which self-configure to form a robust mesh network. The loggers work together to send information to the receiver for viewing on a PC, across a LAN, or remotely across the internet.

PALLET STRETCH WRAPPING MACHINE

Robopac

Robopac is the global leader in the stretch wrapping industry. Robopac line of semi-automatic and automatic pallet stretch wrapping machine combines technology, innovation and experience into products that deliver results you can depend on. Wrapping turntable freezer machine which is used in the foodstuffs field, full stainless steel and suitable up to -30° temperature.

Al Thika Packaging is the exclusive distributor of the world-renowned manufacturers of packaging, inspection, coding and wrapping machinery in the Middle East. Since 1994 Al Thika has been supplying machinery for food, beverages & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Kuwait, Bahrain, Oman and the many other Gulf countries.