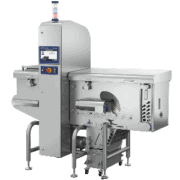

Safeline X-ray Inspection System

X-ray food, pharman and other non-food products Inspection machine which enhance product safety and quality control

The X-ray inspection system by Mettler Toledo Safeline is a leading solution for contamination detection and quality control inspection. Food, beverage and pharmaceutical manufacturers worldwide rely on our in-line x-ray inspection machine to protect the welfare of consumers and safeguard brand reputations, minimise the risk of expensive product recalls and help with regulatory compliance.

Safeline x-ray inspection system offer safety and quality assurance at every stage of the production process for raw, bulk-flow (loose), pumped and packaged products. Neither foil nor metallised film packaging affects the sensitivity of contaminant detection by x-ray.

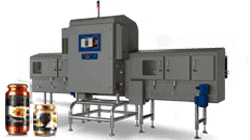

Small and medium product inspection by X-ray

A high-performance X-ray inspection system that delivers great product quality and increased product safety. The X12 system is the perfect solution for small & medium food and pharmaceutical products.

An advanced x-ray inspection available in standard and custom configurations, with single or multi-lane capabilities and integrity checks for outstanding detection performance.

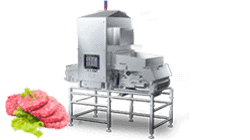

Designed for ease-of-use, the x33 offers high detection capabilities, safeguarding brands and consumers, while its low energy consumption reduces the total cost of ownership.

Automated set-up coupled with intelligent software improve uptime, reduce costs and enhance detection sensitivity to provide the ultimate in product safety with minimal FRR.

Automated set-up coupled with intelligent software improve uptime, reduce costs and enhance detection sensitivity to provide the ultimate in product safety with minimal FRR.