C35 AdvancedLine Checkweigher

Delivers maximum accuracy at throughputs up to 800ppm

High performance checkweighing.High performance checkweigher suitable for challenging weighing applications. Advanced FlashCell™ EMFR technology delivers maximum accuracy at throughputs up to 800ppm. The modular design offers customisation to effectively handle any package type.

Performance Excellence

This system offers the flexibility to support all product sizes and weighing challenges with maximum precision at fast throughputs.

Product Handling Excellence

Achieve maximum process stability and equipment efficiency through transition, transport, stability and sorting options for any packaging format.

Software and Control Excellence

Exceptional process optimization with a wide range of standard and customizable, sophisticated software enhancements and control options.

| Throughput | 800 ppm |

| HMI | 15″ |

| Weighing Range | 3 g – 10 000 g |

| Preferences | Atex Multi-lane Tare Gross Weighing |

| Product Width | 400 mm |

| Hygienic Requirement | Wipe Down ( |

| Maximum Product Weight | 10 kg |

| Combination Options | Vision X-Ray Metal Detection |

| Transport Height | 550 mm – 1,100 mm (± 50 mm) |

| Industry | Pharma Food Other |

| IP Rating | IP54 (optional IP65) IP 65 |

| Accuracy | from ±0.01 g |

| Production Environment | Dusty Explosive Wet Dry |

| Weighing Technology (Load Cell) | EMFR |

| Customisation Options | Bespoke handling OEM Multilane |

| Approval | Weights & measures design approval for official verification (MID certifiable) |

| Weighing Combinations | Contamination Detection Visual Inspection |

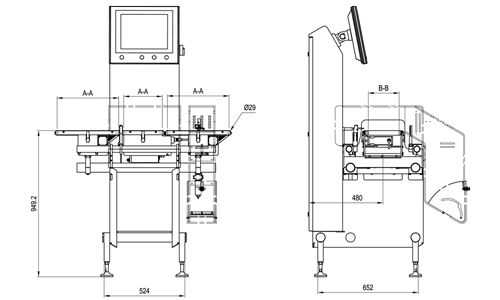

Click the image below to view the diagram.

|

Data Governance to Support Performance

Over 10 different interface / protocol combinations including Ethernet, Fieldbus and OPC technologies enable IoT / Industry 4.0 initiatives so that production data can be accessed, analysed and controlled anytime and anywhere.

Multiple Integration Options

Available as a space saving combination system with either metal detection, vision inspection for label check, x-ray inspection, or Track and Trace technology. Ideally suited as a Critical Control Point to safeguard brand reputation.

Optimised Production Efficiency

Complete line integration to reduce give away via filling machine feedback control. Combined with statistics, this function allows full control of fill levels to fulfil net content regulations whilst keeping costly product waste to a minimum.

Intuitive Operation

The 15″ color touchscreen offers individual user access profiles with password protection. Easily view key weight, production and configuration data in over 30 languages and benefit from machine messages communicated in clear text for easy understanding.

Easy to Clean

With only 4 feet on the floor, the system provides easy cleaning access whilst sloped surfaces prevent product retention. Easy conveyor belt changes and removable catch bins support fast cleaning across different environments.

Weighing Technology and Approval

The high performance EMFR load cell with FlashCell™ technology delivers exceptional accuracy at highest throughputs. Optional MID certification helps to comply with local weighing regulations and reduces costly product waste.

C35 AdvancedLineA throughput of up to 600 packs per minute, a weighing range from 3 g to 10 kg and extremely high weighing accuracy positions the C35 AdvancedLine at the vanguard of checkweighing technology.Its outstanding precision and versatility allow its use in all industrial production situations requiring 100 percent weight control, especially those where demanding and complex application requirements need to be achieved. C35 AdvancedLine checkweighers are available with specialised conveyors and handling options allow for the optimal transport of unstable or open products such as jars, trays and cans. The C35 AdvancedLine has been designed to enhance production line performance, up-time availability and quality. In addition, the C35 AdvancedLine supports all current global food safety standards, legislation and regulations. |

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the main distributor of Mettler Toledo in Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision inspection systems in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.