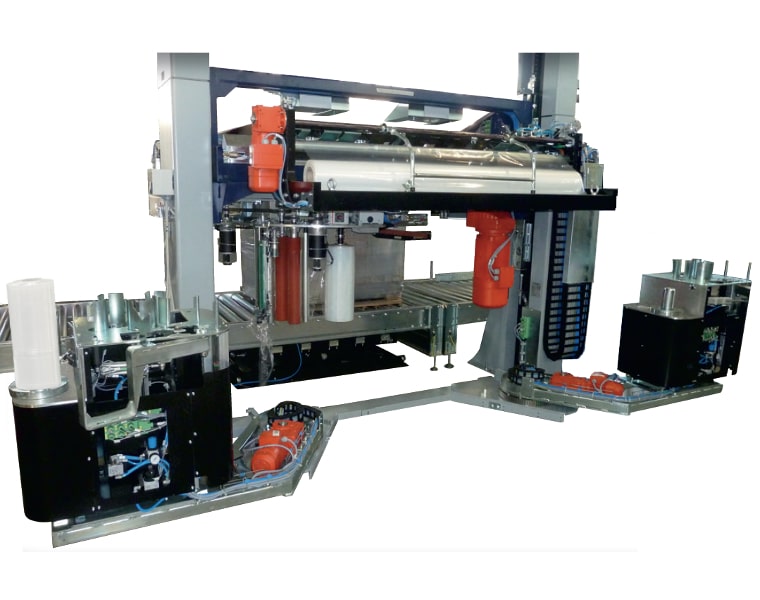

Robopac Sistemi GENESIS CUBE – stretch wrap

Automatic stretch wrapping machine with rotating ring for high productivity.

For the first time, Genesis Cube is fitted with the patented external motorisation device of the pre-stretch carriage thanks to which it is possible to set from the electric control board the maximum force for applying the film produced.

The pre-stretch value of the film applied on the load is continuously variable at all values on the scale up to 400%, it is extremely accurate with consequently increased assurance on film consumption.

Robopac Sistemi – Al Thika Packaging LLC

Al Thika Packaging is an exclusive distributor of Robopac Sistemi in the Middle East. Since 1994 Al Thika has been supplying best automatic horizontal & vertical Stretch Wrapping machines for food & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.

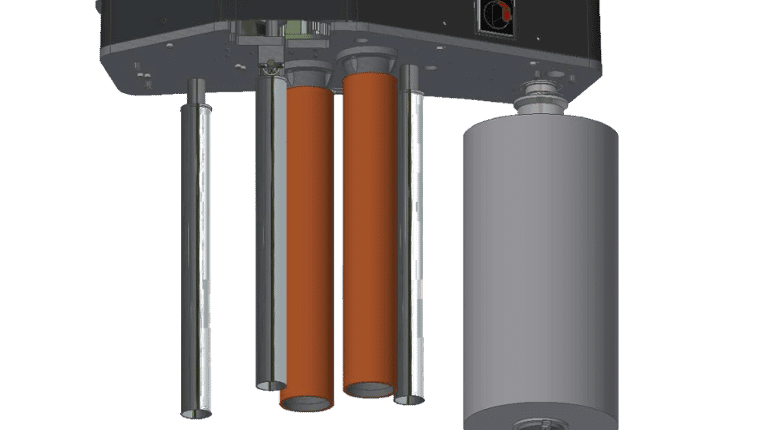

BSCSP CARRIAGE

Patented carriage with double brushless motorisation placed on the structure of the wrapping machine and not in rotation

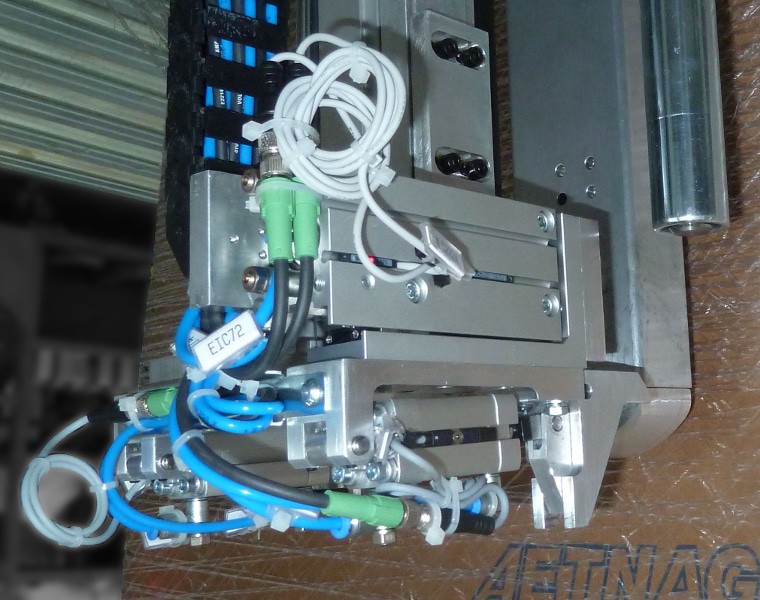

CLAMPS

FUTURA CLAMP

Integrated system with cutting and welding

NIP&TUCK CLAMP

Clamp with wrapping film tail insertion

MAIN OPTIONS

VERTICAL PRESSURE PLATEN

The device can be used with particularly unstable loads

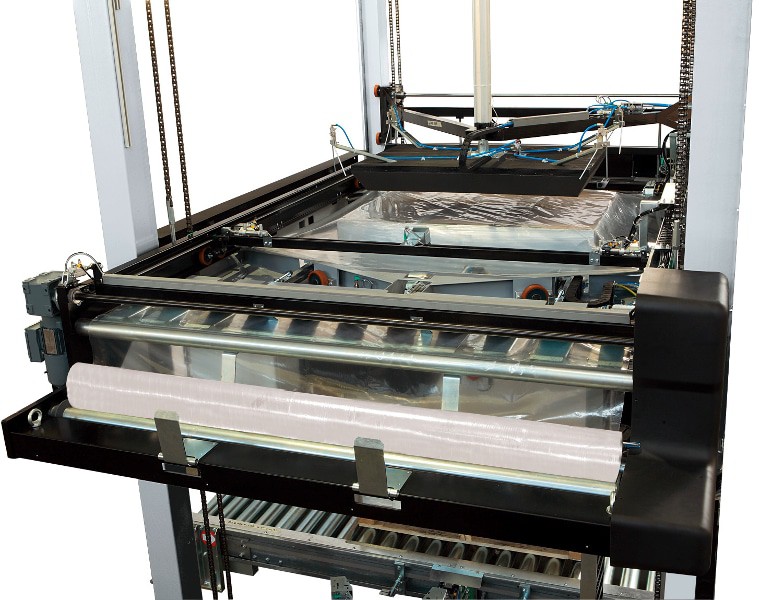

TOP COVER

Device for covering the upper side of the pallet

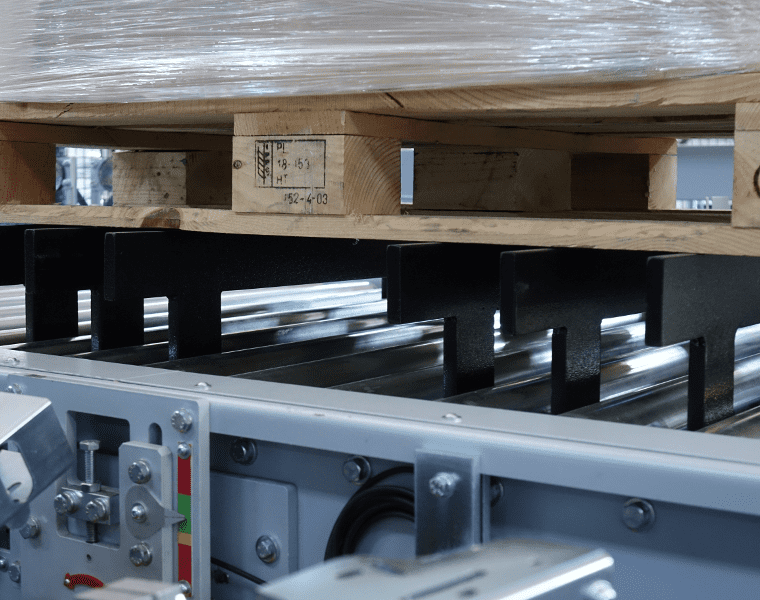

PALLET LIFTER

Pallet lifting system located under the conveyor in the machine centre

ROPING

Device for reducing the width of the wrapping film

VCA4 – CORNER APPLICATOR

Automatic corner applicator device to protect the load

ARC REEL-CHANGE

Automatic device for the replacement of the wrapping reel

DATA SHEET

| STANDARD TECHNICAL FEATURES | ||

| Pallet Dimensions min – max (*) | mm | 500×600 – 1100×1300 |

| Maximum pallet height | mm | 2000 |

| Output capacity (* *) | Pallet/h | 135 |

| Standard pre-stretch carriage | BPSV – Two brushless servomotors placed on the structure of the wrapping machine (patented system), with motion control devices, variable pre-stretch | |

| ( *) Possibility of wrapping the half and quarter pallet | ||

| ( * *) In certain wrapping conditions and defined pallet sizes | ||

| STANDARD ELECTRICAL FEATURES | ||

| Power supply voltage | V | 380 – 400 – 415 ± 5% |

| Power supply frequency | Hz | 50 ± 1% |

| STANDARD PNEUMATIC FEATURES | ||

| Compressed air pressure | Bar | 6 ± 1 |

| REEL FEATURES | ||

| Film reel height | mm | 500 (Standard) – 750 (Optional) |

| Max reel diameter | mm | 250 (Standard) |

| Reel cardboard height | mm | 510 (Standard) |

| Workable film thickness (***) | μm | 17 – 30 |

| TOP Film thickness | μm | 40 – 100 |

| (***) According to film quality | ||