Meet world-renowned packaging and inspection machinery manufacturers ULMA and Mettler Toledo at IFFA exhibition

The leading international trade fair for the meat industry

4th to 9th May 2019 in Frankfurt, Germany

IFFA – The No. 1 for the meat industry – opens its doors again from 4 to 9 May 2019. As the sector’s foremost innovation platform, IFFA will once again bring together all players from the industry, retail trade and butcher’s trade in Frankfurt am Main. Thanks to its clear focus, the world’s leading trade fair for the sector is unrivalled: everything revolves around the most valuable of all foodstuffs – meat.

Good reasons why you should come to IFFA exhibition 2019

- See the innovations being shown by over 1,000 companies from 50 countries

- Meet the market leaders at the same time and place

- Discover the latest meat-industry trends

- Experience the entire spectrum from manufacturing to high-tech

- Make contacts with the international meat-industry community

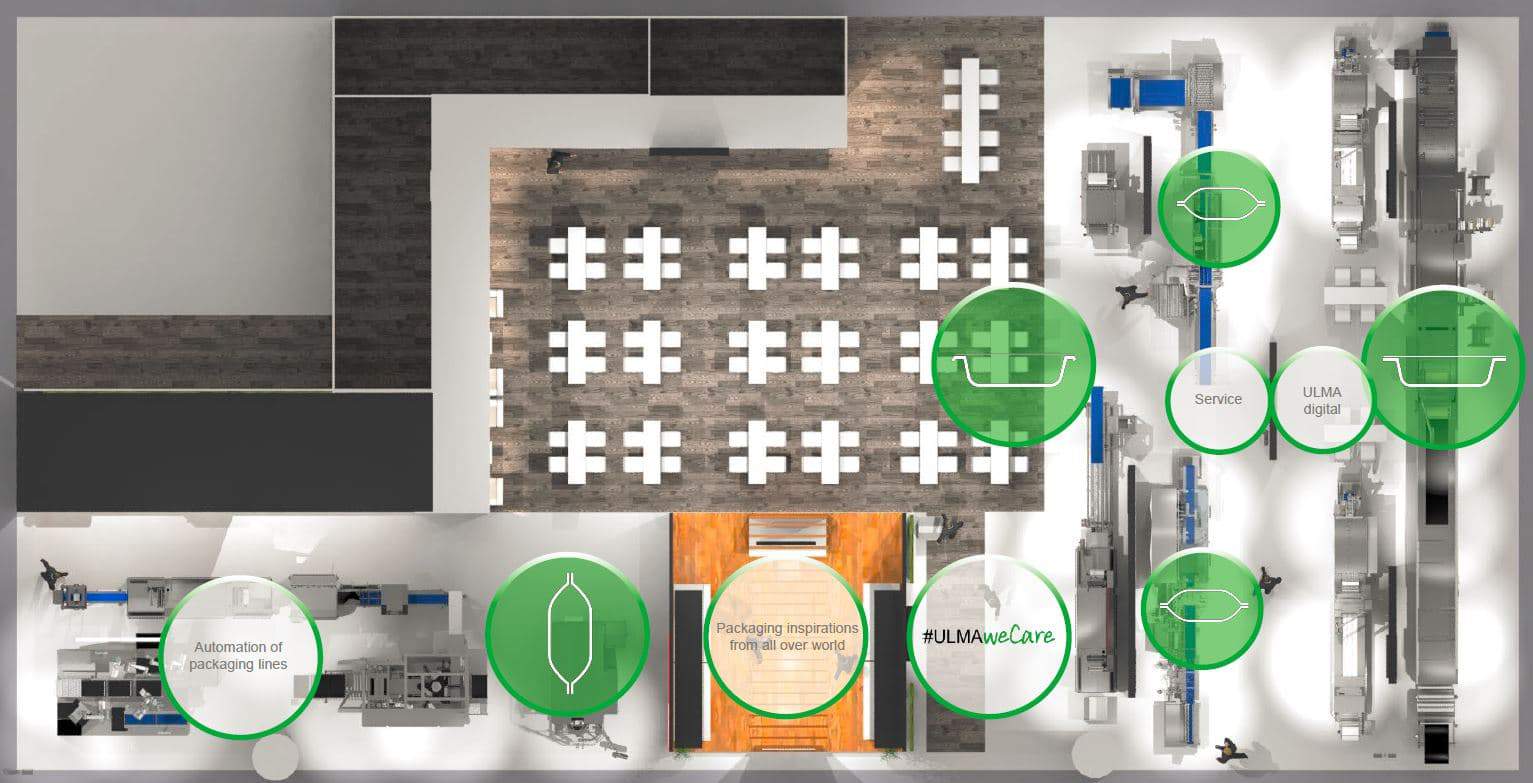

1. #ULMAweCare: sustainable solutions

We are strongly committed to minimise the impact on the environment reducing the amount of packaging required by our solutions, while maintaining the benefits in terms of safety, long-term preservation of products, reduction of product waste, and using more recyclable and compostable materials.

Area #1 will be dedicated to our sustainable packaging where visitors will be able to experience the benefits of ULMA’s most environmentally friendly solutions.

2. Packaging inspirations all over the world

Area #2 will be dedicated to show our best packaging solutions from all over the world. Samples sorted by industry where visitors can check packaging trends from different countries.

3. Automation of packaging lines

Area #3 will be dedicated to automation solutions with a traysealing complete line and a collaborative robots cell.

4. ULMA digital for real business

Area #4 will introduce ULMA’s digital offer through our new UPC 4.0 platform for ease of operation, assistance for maintenance, remote connectivity and increased productivity.

5. Service: taking care of the important things

We know how important it is to ensure that your equipment operates with maximum efficiency, to bring added value to your business. Area #5 will be dedicated to Service.

Mettler Toledo at IFFA exhibition

Hall 11.1, Stand B65

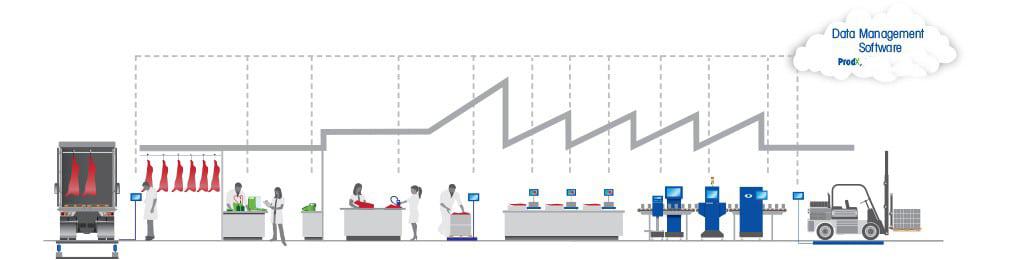

Cost pressure and short shelf life combined with complex regulatory requirements impact meat manufacturers. Packaging trends and market requirements for wider product variety add additional pressure. Mettler Toledo’s solutions are designed to make it easier to detect smaller contaminants, reduce product waste, minimise false rejects, maximise uptime and meet compliance needs.

Whatever your product format and material handling method at the designated critical control point – loose or bulk, pumped, fresh, frozen, or packed – Mettler Toledo has a product inspection solution to meet your needs.

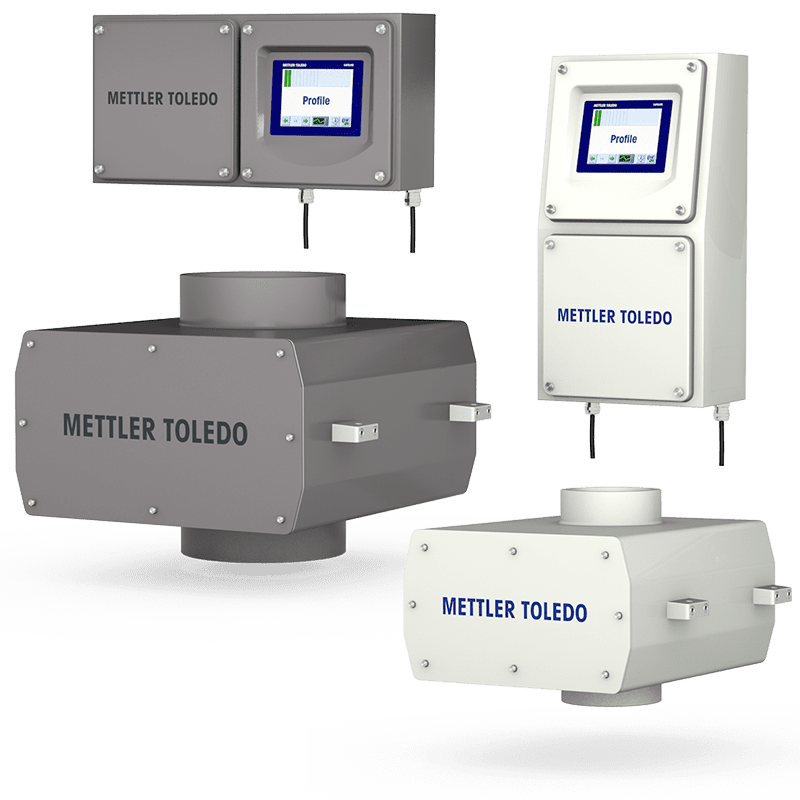

Foreign Body Detection and Rejection by Metal Detector

Wet products such as meat can be challenging for traditional metal detection technology. Our patented Profile Advantage system overcomes “product effect” to detect smaller irregular shaped contaminants, delivering enhanced brand protection. By virtually eliminating false rejects, operator efficiency is improved.

Automation of Quality Control Processes by X-Ray

Manually checking for missing products, damaged packaging, or under- and over-weight products can be a time consuming process.

Quality checks can be automated using X-ray inspection, checkweighing, or vision inspection technology to enhance production line efficiency.

Minimise Overfill to Reduce Waste by Checkweigher

Overfilling results in unnecessary product giveaway and leads to increased costs. Using a dynamic checkweighing system ensures each and every product is inspected to guard against under- or over-weight products and comply with weights and measures legislation.

Visit Mettler Toledo stand to find out more product inspection solutions for the meat industry.