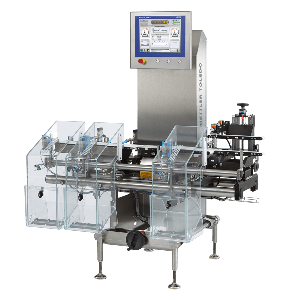

Garvens C35 Pharma Checkweigher – checkweighing

Tailored for Pharmacist’s

The C35 Pharma checkweigher is fitted with numerous configurable options and features to meet the requirements of today’s pharmaceutical production companies.

Ensure Consistant Product Quality

The checkweigher system eleminates recurring errors to ensure a consistant and flawless product quality to protect consumers and brand reputation.

Simple Production Line Integration

The system can be integrated into production lines with ease, variety of data communication interfaces and wide range of options.

Product safety and Consumer Protection

Lockable catch bins and smart software options guarantee increased product safety to meet the requirements of pharmaceutical companies.

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the exclusive distributor of Mettler Toledo in the Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision product inspection systems for food and non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.

Sophisticated Solutions for Pharmaceutical Serialisation Compliance

A modular checkweighing design allows printing, optical verification and tamper evident labelling equipment to be integrated into a compact checkweigher/serialisation solution. The efficient printing of a unique series of digits, data matrix codes or barcodes provides Track & Trace capabilities to meet current and future legal requirements. Tamper-evident adhesive labels are applied for maximum product safety, consumer and brand protection.

End-of-Line Completeness – Checking of Multipacks

Following the pharmaceutical production process, the secondary and sometimes tertiary packaging of products needs to be checked for completeness, too. Again a checkweigher provides a checkpoint for 100% of cartons and boxes at the end of the packaging line.

C3570 Pharma Checkweigher Specification Table

| Load Cell | EMFR |

| Accuracy (at 3 Sigma) | From ± 0.1g |

| Checkweighing Range | Up to 300g |

| Throughput (pcs./minute) | Max. 600 |

| Approval | “Weights and Measures” / MID certifiable |

| Product Preset Memories | 200 |

| Weighing Belt | D15 high performance weighing belt |

| Terminal Screen | 15″ color touchscreen TFT, 1024×768 pixels (XVGA) |

| Standard Sorting Device | Air jet |

| Power | 115 / 230 V~, 50 / 60 Hz, 1 phase, 500 VA |

C3570 Pharma Checkweigher Features and benefits

| Simple Integration and Smooth Operation In your production processes – with a maximum uptime and trouble-free refitting further down the line – from the start the system architecture is designed with practical scenarios in mind. |

|

| Up to 33% Higher Performance Implies high throughput with accuracy to promote tighter manufacturing tolerances in production. Improved processes mean an increase in overall equipment effectiveness to maximise your profits. |

|

| Maximum Productivity The transfer unit which is designed for exact product transfer as well as the detection of open flaps and askew packages increase system availability and minimise production line stoppages. |

|

| Maximum Process Reliability A wide range of options – both electromechanical and software – are available, ensuring that the production processes can be controlled precisely to ensure maximum safety. |

|

| Extensive Service Support An extensive service network guarantees timely support plus availability and quick delivery of spare parts. This reduces downtime and keeps processes running smoothly. |

|