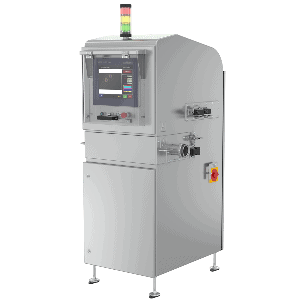

X38 X-ray Inspection system

Inspection for Pumped Product

Safety of Pumped Products

The X38 x-ray system can inspect pumped products such as slurries, semi-solids and fluids, ensuring food safety before final packaging and further value is added to the product.

Wide Range of Food Applications

This food x-ray system covers a wide range of pipeline applications including jam, yoghurt, fruit purees, minced meat, chicken pieces and more.

Hygienically Designed

Class-leading hygienic design following GMP, NFS and EHEDG principles with IP69 as standard and highly featured CIP (clean in place) features.

High Throughputs

Inspection at a rate of up to 14 tonnes of pumped product per hour. Automatic calibration can be performed in less than 20 seconds, maximising uptime.

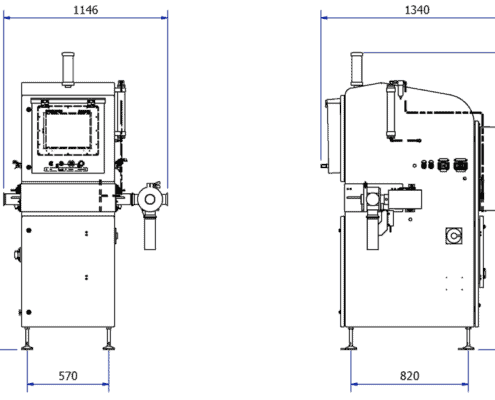

X38 Specification Table

| Casing Material | Stainless Steel |

| Connectivity | External USB, Ethernet port |

| Max. operating pressure | 3 bar typical, 10 bar peak |

| Cooling method | IP69 Air Conditioner |

| Display | Full colour TFT 15inch touch screen |

| Flow rate | Up to 14 tonnes per hour |

| Operation humidity | 30-85% |

| Pipe diameter | 3” or 4” (75mm or 100mm) as standard |

| Pipe fittings | Typically tri-clamp or RJT |

| Power options | 60Kv 5.0mA |

| Operating Temperature | 5-40°C |

| Traceability | Full event log history |

| X-ray detector | Highly stable USB detector with 0.8mm diode |

| X-ray emissions | < 1microsievert per hour* |

| X-ray protection | Interlocked pipeline manifold |

Mettler Toledo – Al Thika Packaging LLC

Al Thika Packaging is the main distributor of Mettler Toledo in Middle East. Since 1994 Al Thika has been supplying a wide range of machinery including Garvens dynamic Checkweighing systems, Safeline X-ray inspection, Safeline integrated metal detection systems and CI-Vision inspection systems in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Bahrain, Oman and the many other Gulf countries.