Machinery solutions for fruits and vegetables

Packaging machine, sorters, shrink & stretch wrapper and coding printer for fresh produce

Al Thika Packaging offers you the broadest range of fruit and vegetable machinery which includes packaging machines, sorters, shrink & stretch wrappers, product inspection equipment and coding printer and much more. We helping you in your search for the optimal, sustainable packaging for your fresh produce product.

SUSTAINABLE AND ECO-FRIENDLY SOLUTIONS

Al Thika Packaging is fully aware of the increasing use of plastic. For saving our planet, we are providing sustainable packaging machinery solutions for fresh produce fruit and vegetable.

SORTING & WASHING MACHINE SOLUTIONS FOR FRUIT & VEGETABLE

We are offering processing, sorting, washing, drying equipment and automation for fresh produce fruit and vegetable that enable processors to deliver high-quality, safe food easily, efficiently, and cost-effectively.

SORTING MACHINE SOLUTIONS

WASHING & DRYING SOLUTIONS

NET PACKAGING MACHINE SOLUTIONS

Machinery and consumables for fresh produce

Giró offers a wide range of net packaging machine solutions in the net which can cover all the requests made in the horticultural sector.

In addition, the integrated packaging systems offered by Giró minimise human intervention in the process, lowering handling costs and reducing downtime packaging.

The range is divided into two types of packaging: thermal welded net bags and clipped net bags.

CLIPPED NET BAG

Low cost packaging system with high visibility.

Traditional net packaging with simple structure thanks to the use of a metal clip to close the bag. It allows high visibility, product breathability and high productivity.

Range of weight: 500 g – 3 kg.

THERMAL WELDED NET BAGS

Appreciate the content.

An economic and ecological packaging with a printed or neutral band on its top keeping rest of the packaging with high visibility in order to show the fruit at its best.

Range of weight: 500 g – 3 kg.

Handling: handle or holes.

Recommended film width: 90-120 mm.

The GH-20 is a strong and reliable semi-automatic net packing machine that makes bags from the tubular net.

It is extremely easy to use. The product to be packed must be loaded into the tube with tubular net and, with one easy action, the device clips the bag and cut the net on the tube to be ready for the next packing cycle.

An essential item is to add a label including all the product information like a barcode, price or any other necessary data for the sale.

Bagging machine to make clipped net bags, with automatic tube change and output up to 42 bpm, for horticultural products like oranges, mandarins, lemons, grapefruits, potatoes, onions, etc.

PEG-12/160 Weigher

High performance 12 buckets static weigher

The PEG-12/160 is a 12 buckets static weigher. Includes advanced algorithms capable of reaching a high productivity compared to other 12 buckets models. It is the ideal weigher for feeding 2 GirBagger welding machines, 2 CA-9S clipping machines or 3 Girplus/Girsac welding machines.

Fruits and vegetables over 40 mm diameter are to be processed: potatoes, onions, garlic, orange, clementine. In case produce diameter below 40 mm, small fruit kit for PEG12/160 enables produce handling such as chestnuts, small clementines, walnuts, etc…

MULTIPLE PACKAGING MACHINE SOLUTIONS

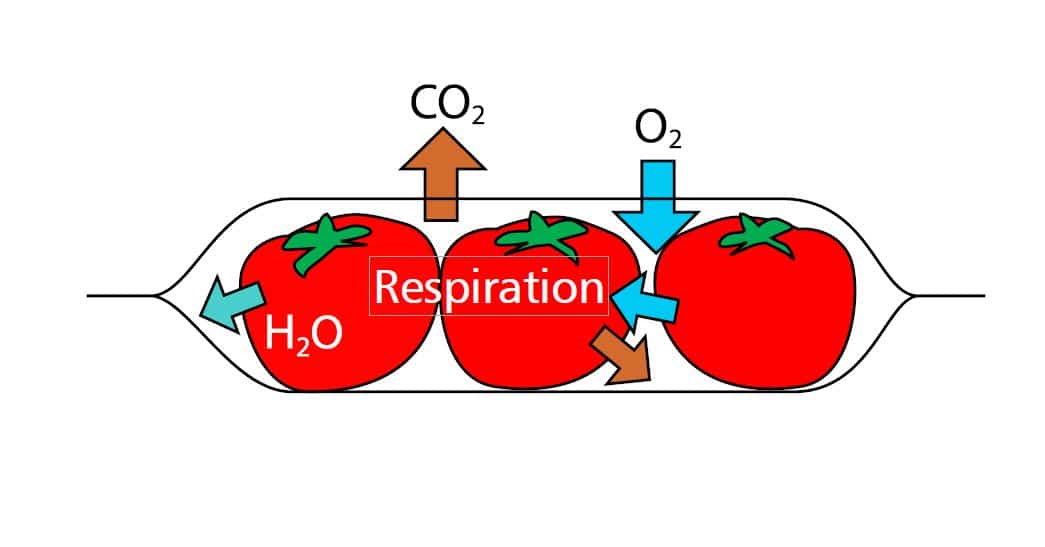

After they are harvested, fruits and vegetables live on and have a limited shelf life. To extend it, ULMA offers you the widest range of packaging solutions on the market for the fruit and vegetable sector helping you in your search for the optimal packaging for your product.

ULMA Packaging makes use of its specialisation and knowledge in the Produce sector by offering the widest range of packaging solutions on the market, thanks to the possibility of choosing between five different packaging systems: Horizontal Flow Pack (HFFS), Vertical Flow Pack (VFFS), Thermoforming, Traysealing, and Stretch Film, each with their own specialised technology for extending the conservation of each fruit or vegetable.

An economic tray packing for fresh vegetables & fruits that protects the product and enhances its aspect with a printed film, which allows using labelling for the identification and characteristics.

Thermoforming and Traysealing packing

Fresh vegetables & fruits in rigid or flexible trays which allows stacking for their transportation and display. The perfect package for ready to eat vegetables & fruits. Optionally, tray can have a rigid cover to increase mechanical protection.

Flow Pack packaging

The flow pack wrapping protects the product and improves its presentation , as well as their identification and optionally offers the possibility to extend the shelf life of the product controlling the moisture and breath.

Flow Pack and Vertical packaging

Fresh vegetables and fruits in horizontal and vertical flow pack. Shrink packs for whole or portions protect product allowing labelling. Vertical pack with steady bottom option to display packages on shelves.

Eepera labelling systems and software solutions designed to meet the requirements of the fruit and vegetable industry. Learn more about our robust machine solutions, designed for the highest demands in the fruit and vegetable industry. Whether dust, dirt or temperature extremes.

ATS is providing perfect banding solutions for fruits & vegetable. The desired number of stem vegetables are removed from the conveyor belt and then banded. The machine has a vertical construction to prevent the dirt particles from falling into the banding assembly, thus protecting the individual components from possible contamination. This guarantees uninterrupted and low-maintenance operation.

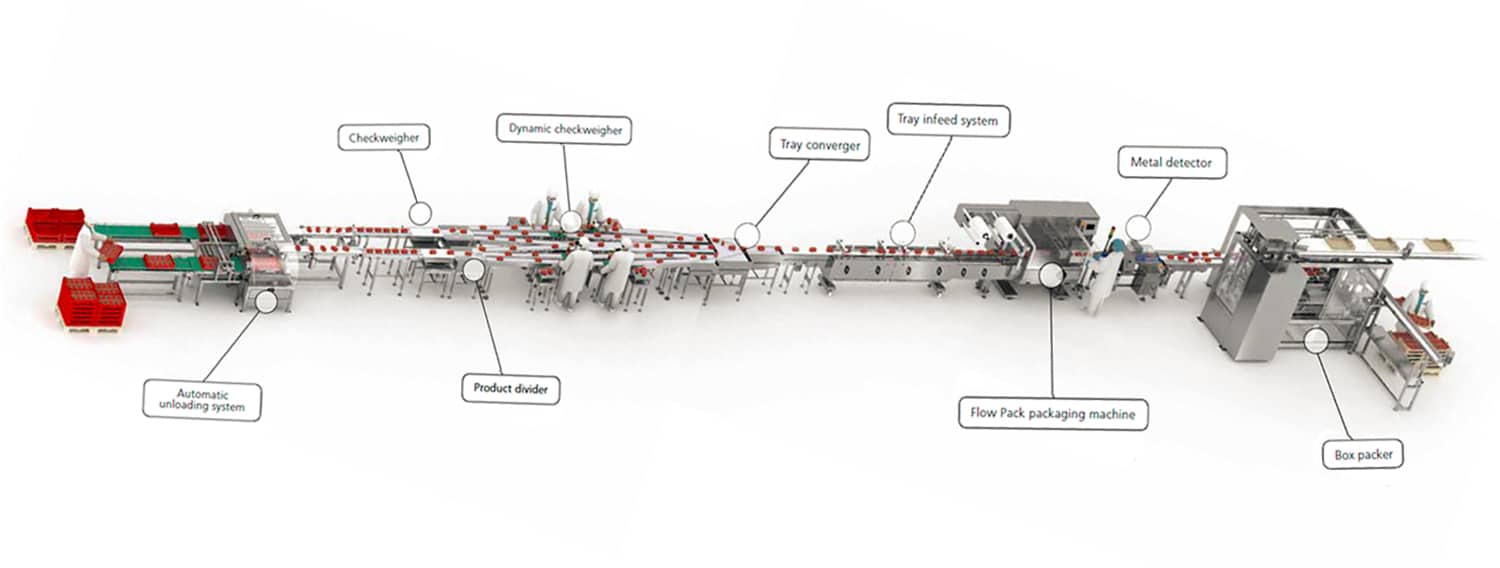

Accurate product weighing and the removal of a contaminated product are two major factors contributing to maximising yield in the fruit and vegetable industry. Checkweighing and metal detection combination systems are available to address both issues in a new single compact unit.

Contributors to yield improvement

A significant contributor to maximising yield is correct package weight. The ability for manufacturers to dynamically weigh every packaged product, rather than adopting a random sampling approach, offers major potential benefits. Highly accurate load-cell technology developed by Mettler Toledo Garvens provides complete control of package filling for optimised production-line performance. The identification and removal of under or overweight products not only minimise customer complaints but also avoids costly product giveaway.

Detecting Contaminants

The inclusion of contaminant detection equipment in food-production processes is a pre-requisite to satisfy the requirements of food safety standards. The nature of some fruits and vegetables in bulk formats can present challenges to metal detectors, leading to the risk of false triggering and the subsequent rejection of good product – damaging yield performance.

Inspection to support compliance

The implementation of a comprehensive product inspection program which includes the installation of a metal detection device at designated Critical Control Points (CCP’s) in the production process supports compliance with legislation, regulations and retailer codes of practice.

Markem Imaje provides the reliable coding printer that you need for all aspects of the fruit and vegetable industry. Whether you are printing best before dates, ingredients, logos or barcodes, Markem Imaje printers will produce the highest quality codes, even in your demanding environments. Powered by our intuitive CoLOS software, hot melt, print & apply and laser technologies will minimise operator errors while increasing your sustainability and reducing your total cost of ownership (TCO).

More about coding solutions for fresh produce.

Al Thika Packaging is the exclusive distributor of the world-renowned manufacturers of packaging, inspection, coding and wrapping machinery in the Middle East. Since 1994 Al Thika has been supplying machinery for food, beverages & non-food industries in Dubai, Abu Dhabi, Sharjah, Fujairah, Ras Al Khaimah, Ajman, Umm Al Quwain, Al Ain – UAE, Saudi Arabia, Kuwait, Bahrain, Oman and the many other Gulf countries.